Table of Contents

Safety is a vital concern in a warehouse or distribution center, which often involve the storage of hazardous materials, use of heavy machinery, and regular flow of goods. So installing warehouse safety signage can be essential to keeping risks at a facility as limited as possible.

Warehouse safety signage can be used to warn people of dangers or make them aware of rules designed to keep a space safe, with such signage designed to be brightly colored, easy to read, and sometimes even including lights and sounds to guarantee it catches attention.

In general, warehouse safety signage must comply with specific requirements, such as those established by the Occupational Safety and Health Administration (OSHA) in the United States.

SEE ALSO: Warehouse equipment installation: 4 great reasons to hire a setup professional

In general, warehouse safety signage should catch the attention of personnel handling goods and heavy machinery, and guide them in the event of an emergency. It also helps to locate and identify everything from protective facilities to emergency exits or first aid equipment.

Below, we list the most common types of warehouse safety signage. You can include them in your warehouse setup checklist to keep your workspaces free of hazards and without interrupting your operations.

At Serviap Logistics, we are experts in installing warehouse safety signage in Brazil, Mexico, and the United States. Contact us to find out how we can help you.

4 types of warehouse safety signage

Warehouse safety signage is necessary in a wide range of different environments within a facility, from aisle marking to rack load capacity.

1) Aisle warehouse safety signage

Aisle signage optimizes work environments, limits heavy loads, increases productivity, and helps maintain safe spaces. Numbering aisles and placing row identifiers, product categories, or other relevant details is necessary to help workers identify where they are and easily access the goods they need.

Warehouse safety signage, specifically in aisles, can be suspended from the ceiling or attached to the shelves. Its design can be diverse, depending on the location and the machinery that moves through the area. In general, however, it should have large letters and communicate something specific, such as hazardous substances or the presence of cleaning personnel.

Aisle signage should be considered when choosing the warehouse layout design that best suits the space and storage needs. This protection feature will increase the safety of employees, goods, and the building and speed up the workflow inside the warehouse.

2) Forklift traffic

It is necessary to place warehouse safety signs in loading and unloading areas and storage spaces, because these spots are where forklifts, the electric or combustion machines used to lift and transport heavy loads without manual effort, frequently circulate. Warehouse safety signage helps to direct these vehicles to minimize risk.

There are several types of forklifts, some of which even have radar or radiofrequency pedestrian detection systems. However, by supporting loads of up to one ton and reaching speeds of up to 30 kilometers per hour, they represent a danger to workers, storage equipment, and goods. This means plenty of signs to ensure that everyone working there knows where they can and cannot be.

Warehouse protection barriers can help minimize damage to shelving and infrastructure caused by forklifts. Still, ongoing training of operators is also necessary, and, above all, warehouse safety signage in high-traffic areas and zones of potential collisions.

3) Load capacity

Clearly and accurately marking load capacities on racks —and any work equipment used to store and move goods and materials within the warehouse or distribution center— helps avoid workplace accidents. Staff within the warehouse should not be expected to make their own assessment but rather follow guidance.

When this type of warehouse safety signage is correctly installed and displayed, personnel are more aware of not overloading the storage equipment. This will prevent possible collapses that, in turn, can cause losses and harm to workers.

To ensure correct warehouse safety signage, which considers the load capacities according to the materials and the quality of the racks, one option is to hire the services of a warehouse setup consultant. These experts will help their clients to verify that the signage is correctly positioned and appropriate.

4) Health and safety risks in goods

Besides the warehouse safety signage placed in aisles, to indicate forklift traffic and specify load capacities on shelves, it is necessary to display specific placards to ensure the health and care of all people who enter a warehouse. While permanent staff may be well aware, visitors need to be particularly aware fo these dangers.

For example, when handling hazardous and toxic materials, in addition to using gloves, boots, special suits, goggles, and helmets, employees should be reminded to wash their hands, place their protective equipment in a specific location and, if necessary, pass through a disinfection area.

Safety protocols should be communicated on time to everyone involved in the warehouse operation, but also be aware of the types of signage within the warehouse. Proper placement of these signs helps to make personnel more aware of the hazards in these workplaces.

Warehouse safety signage: general considerations

As we mentioned at the beginning, each territory has its safety regulations, which govern operations within workplaces, such as warehouses and distribution centers, so we suggest you review the standards in your region to avoid problems of non-compliance and accidents.

In the United States, for example, the Occupational Safety and Health Administration (OSHA), an agency within the Department of Labor, is responsible for ensuring that all workers operate in a safe and healthy environment.

According to OSHA, all warehouse safety signage must have rounded or blunt corners and be free of sharp edges, burrs, splinters, or other sharp projections. Signs can be made of various materials, such as metal, plastic, or vinyl, and can be attached to shelving or hung from the ceiling.

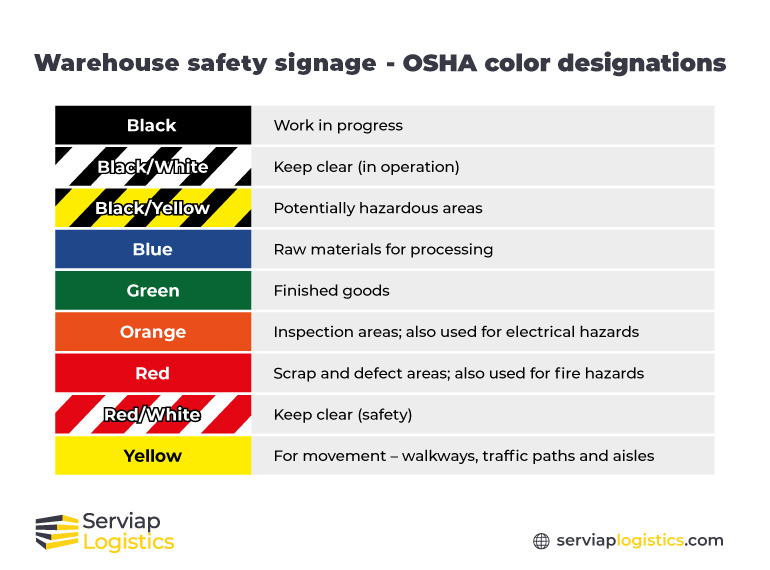

Shapes can vary, but the triangle is often utilized as a warning sign; the circle is a prohibition or obligation, while squares and rectangles indicate everything from hazards to safe areas. Still, their meaning will depend on the colors and symbols used.

OSHA classifies warehouse safety signage in the following manner:

- Danger: as its name suggests, this sign indicates specific risks, like fire. In these prohibition signs, the color is usually red since it gives an alarm and stop signal, such as do not enter an area.

- Warning: warning signs have yellow as the standard background color with black letters. In some cases, orange is also used. They serve as a call for attention or verification.

- Caution: this type of warehouse safety signage has a white background, green border, and white lettering. If the background is entirely white, the letters will be black. They are used as rescue or help signs but also to indicate exits, passages, and aid stations.

Serviap Logistics assists clients in the installation of warehouse safety signage

At Serviap Logistics, we supply and install warehouse safety signage in Brazil, Mexico, and the United States. Our team focuses on providing simple, easy-to-recognize signs for people and on compliance with local legislation.

We offer elements for warehouses and distribution centers, including shelving, labels, floor marking, and collision protection. And if you need project management services to supervise the installation, remodeling, or relocation of your warehousing business from start to finish, we can help you.

Our customers and partners are satisfied with our services and come from a wide range of industries, including automotive, e-commerce, and wholesale.

As a family-owned company with roots in Mexico that has grown internationally, we are committed to service excellence and pride ourselves on providing personalized attention to each customer.

To maintain the highest safety standards in each project we participate in, we have expert personnel in local regulations, such as OSHA certification in the United States.

Contact us to learn more about our warehouse safety signage installation services. If you liked this article, check out the rest of our coverage.