Table of Contents

Warehouse racking layout directly impacts the operational efficiency of a facility, as it enhances space utilization, streamlines inventory management, and facilitates seamless order fulfillment.

A well-designed warehouse racking layout is one of the foundations for ensuring that goods are handled with minimal effort, reducing the risk of errors and delays. When you achieve the best flow of products, you also save time and costs.

Managers need to consider the space limitations, the inventory characteristics, and the handling equipment used by the team. All of these requirements help to develop the ideal solutions for warehouse racking installation, based on one’s budget and time frame.

Contact us if you are looking for a supplier or installer of warehouse racking in Brazil, Mexico, or the United States.

Warehouse racking layout: 4 common rack types

There are compelling aspects to incorporating different types of racks in your facility. Varying options can influence an operation’s capacity to optimize inventory turnover. Discovering their pros and cons, as well as how to combine them, is essential to have more control over products and processes, especially because about 80% of industrial storage is made with pallet racking, according to Frank Cirello for MMH.

1) Selective

A selective warehouse racking layout is a series of vertical frames and horizontal beams. The fundamental feature is it allows for individual selection and access to each pallet or item stored on the shelves. This means you can access any pallet directly without having to move other ones out of the way.

This layout is highly cost-efficient, as it has the simplest design. It is also easily adjustable because it can accommodate different pallet sizes. However, storage density tends to be lower than other methods. You may also prefer this method only in areas with high ceilings so that you can fully take advantage of the vertical space.

2) Drive-in

In a drive-in racking system, forklifts drive straight into the racking structure to place or retrieve pallets. Pallets are stored on horizontal rails that form multiple lanes within the racking system. The machinery enters the system from one side and travels along the lanes to deposit or retrieve pallets.

Since there are no aisles between every rack, the storage density is higher compared to the selective racking system. By utilizing fewer aisles, the drive-in warehouse racking layout makes efficient use of available space, which can lead to cost savings in terms of square footage. This technique works best for storing similar products that are uniform in size.

3) Pallet flow

The pallet flow warehouse racking layout uses inclined roller tracks or skate wheels to create a flow-like movement of pallets from the loading side to the unloading side of the rack. It’s particularly well-suited for high-density storage of goods inventory management requirements.

Even though initial costs can be higher, this system is great for industries where inventory turnover is important. It facilitates daily operations, as workers can easily access the pallets at the unloading side, which are at a lower level. Pallet flow racking can be integrated with automation systems, such as conveyor systems, to further optimize warehouse material handling processes.

4) Push-back

Push-back racking can maximize storage density while maintaining efficient inventory rotation. It utilizes inclined rails or tracks to store multiple pallets in a deep configuration. This warehouse racking layout is a suitable solution for facilities with a need for dynamic storage and selectivity.

The inclined rails are set at a slight decline, utilizing gravity to move the pallets smoothly along the rails toward the unloading side, reducing travel time and forklift movement. It’s a good option for industries with products that have a moderate turnover rate. This layout also eliminates the need for multiple aisles but requires an initial investment in the rolling carts and rails.

The importance of warehouse layout design

Following an efficient warehouse layout design is crucial to facilitate the production line. So, one of the first things to do is map your space of operations. Assess the loading and unloading areas, as well as the stages of receiving, storing, picking, and dispatching goods. When you map these areas spacially, you can make the most of the available spaces, controlling the products and optimizing flexibility.

Once you do that, you can focus on designing your warehouse racking layout to maximize your physical storage. First, identify your inventory needs. Consider the aspects of the items you plan to store, including size, variety, and expiration dates. Additionally, you should take into account how frequent the product rotation is in your warehouse, according to the type of your business.

For products that are stored in larger quantities but require less frequent access, you may need a high-density warehouse racking layout, using pallet flow and drive-in racks. On the other hand, low-density layouts, like selective rack systems, are ideal for items that need to be accessed frequently and individually. Choosing correctly helps you plan for expansion and increase your storage space if needed in future scenarios.

When you have a clear understanding of your racking system needs, you can find the most cost-effective solution and invest in the right equipment and racking products that align with your warehouse needs. Once your needs are well-defined and you’ve established an optimal racking arrangement, you can proceed to compare prices and find the best supplies and professionals.

Additional aspects to optimize your warehouse racking layout

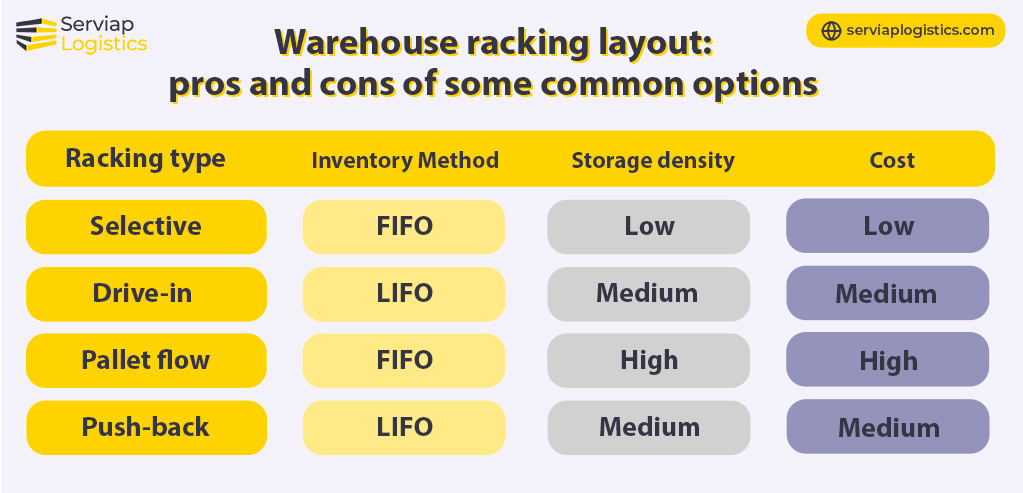

Beyond design and project management, other aspects can optimize your warehouse racking layout choices. For instance, deciding between LIFO (last-in-first-out) and FIFO (first-in-first-out) inventory retrieval is pivotal in defining suitable rack strategies. For the first approach, you can maximize space with drive-in and push-back racks. However, for faster movement, you can use selective and pallet flow racks.

To guarantee a smoother flow of items and ensure they are found quickly and efficiently, you need proper rack labeling. Labels create a guiding system for workers to retrieve products faster and more accurately. They are a key part of daily operations and must be easily readable by a wide variety of workers, from machinery operators to dispatching operatives.

Another important thing is analyzing your facility conditions. Measure your space, including heights, aisle widths, and square footage. Also, beware of obstacles such as doors, mezzanines, and columns. This helps you identify the dimensions for your pallets, which affect your layout preferences. When you have this data narrowed down, it becomes easier to create the most efficient system.

Finally, don’t forget to ensure legal compliance with safety standards regarding storage and racking. Most regulatory institutions, such as OSHA in the US, or ABNT in Brazil, will have specific demands for racks in warehouse setups. These include distance from walls, ceilings, obstacles, and so on. You also have to be careful with the maximum weights and heights permitted, to avoid fines and accidents in the workplace.

Serviap Logistics offers warehouse racking layout services

At Serviap Logistics we assist clients with warehouse setup services in Brazil, Mexico, and the United States. Our services include including racking, signage, floor marking, and collision protection. We also supply labels and offer project management to oversee a warehouse refit or relocation from start to finish.

Our ability to hit tight deadlines without sacrificing safety or quality has seen us become the trusted partner of some of the biggest and best-known companies in the world wherever we work, covering industries such as agrioculture, automotive and e-commerce, among others.

Contact us to learn more about how we can assist you. Or book a call with a consultant.