Table of Contents

Warehouse layout optimization is all about about making the facility more efficient and people-friendly by smoothing workflow, enhancing safety, and maximising usage of the space.

A provider of warehouse layout optimization services — sometimes referred to as a warehouse setup consultant – will help get the most out of an existing warehouse or distribution center, or may be hired to make sure that a new space is properly exploited.

As well as evaluating how a space is organized and existing equipment is distributed, a warehouse layout optimization specialist will also supply and install key infrastructure. This can include the likes of racking, collision protection, signage, and floor marking.

Contact us if you need assistance with warehouse layout optimization.

The importance of warehouse layout optimization

Before embarking on an optimization project, it is essential to analyze your current setup and identify areas that need improvement. Create a detailed map of the various areas within the facility, such as those for receiving goods, storage, picking, packing, and shipping.

It can be a good idea to use design software or work with warehouse design experts to ensure your plan fully exploits the space available and builds in maximum efficiency, while taking into account any potential future developments you anticipate.

Guaranteeing the best usage of space means understanding the facility’s capacity, how much storage space you require now and for the future, and what other infrastructure you will need. Because the best storage system for you will depend on a combination of those factors.

Which goods are going to be moving through the space, as well as how they will be moved, will also need to be taken into account, affecting key aspects of your facility, such as aisle width.

In the case that a wide variety of goods will be moving through the space, the likes of a dynamic storage system may be needed, allowing easy access to frequently picked items and a more static storage for slower-moving products. Such forward planning will enhance picking efficiency and minimize unnecessary movements within the warehouse.

Properly setting out and segregating different areas based on the flow of work will also be another area of consideration, in order to guarantee that movement between receiving, storage, picking, packing, and shipping zones is as efficient as possible.

Beyond pure operational effeciency, it is also important to take into consideration the people using the space and the areas they require, such as break rooms and restrooms. It is good to make sure they are designated and positioned to be as convenient as possible to the majority of people.

A final obvious factor that must also be considered — which a professional provider will be well-placed to help with — is making sure that all decisions are made so that the facility will remain compliant with any relevant regulations. Those include rules laid out in accordance with OSHA in the United States, ABNT in Brazil, and NOM in Mexico.

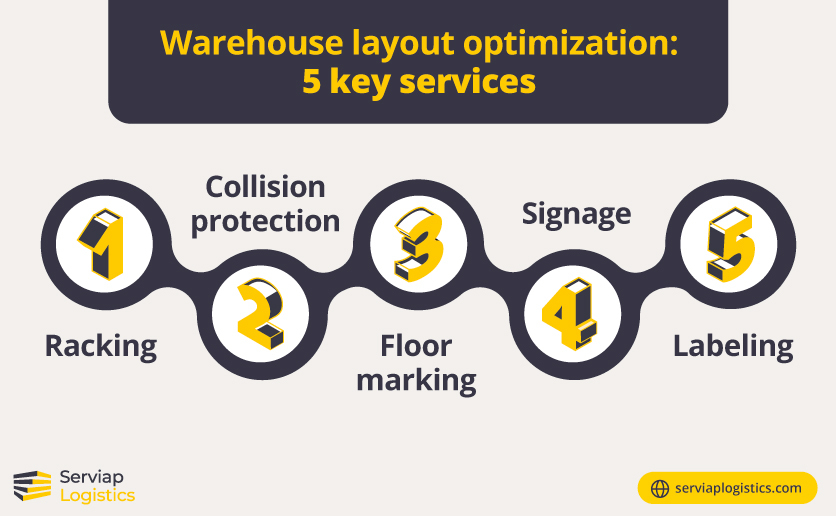

Warehouse layout optimization: 5 key services

Warehouse layout optimization involves bringing planning all of the infrastructure needed for an operation to run successfully in order to maximize the space available and build efficiency into the facility’s processes.

Some key elements of that infrastructure include:

1) Racking

Racking is the backbone of many warehouses and distribution centers, so getting your warehouse racking layout right is an essential part of any optimization plan. A well-designed system ensures that goods are stored in an organized manner, facilitating faster picking and restocking processes.

2) Collision protection

In a bustling warehouse environment, collisions between equipment, personnel, and inventory can lead to damages and safety hazards. Warehouse protection barriers such as guardrails, bollards, and column barriers prevent accidents and contribute to a safer environment, reducing the risk of injuries and damage.

3) Floor marking

Warehouse floor markings designate specific areas for different functions, such as storage, packing, and shipping. Color-coded markings can help guide employees and equipment, reducing the risk of congestion and improving overall safety. A visually organized warehouse floor serves as a blueprint for efficient operations.

4) Signage

Well-placed warehouse signage provides essential information to direct people to aisles, emergency exits, and other areas, as well as providing key information such as safety instructions. So an important element of any warehouse optimization process is guaranteeing that signage is used in the most efffective way possible.

5) Labeling

Warehouse labels are critial for stock management and facilitating many day to day activities within a facility, such as line picking. A wide variety of labels are available to suit different uses, and optimizing a warehouse or distribution center will also involve reviewing the labeling system to make sure it is as effective as possible.

Additional warehouse optimization services

Beyond helping you get key infrastructure right, a provider of warehouse layout optimization services may also offer a range of additional services, which can be important for boosting productivity and efficiency within a facility.

An example is industrial cleaning services, which ideally should be contracted periodically to guarantee the elimination of the deepest dirt and grime, which day-to-day cleaning may not adequately tackle. This can be crucial to keeping the space compliant with regulations, working at maximum efficiency, and people-friendly.

Another additional service that a warehouse layout optimization expert might offer is equipment maintenance and repair, which should also be undertaken periodically to extend the lifespan of key infrastructure, as well as guaranteeing that that space remains compliant with all safety regulations.

Assistance with staffing via business process outsourcing (BPO) or recruitment process outsourcing (RPO) is another type of additional service that a warehouse layout optimization specialist may offer, which can be particuylarly attractive to businesses that are just starting out, or which are relocating.

In many cases your warehouse layout optimization provider will offer project management services, in which it will provide a package of the key and additional services outlined above, and oversee a warehouse setup or refit from start to finish.

Serviap Logistics offers warehouse optimization services

At Serviap Logistics, we supply and install a range of warehouse equipment in Brazil, Mexico, and the United States, including racking, signage, floor marking and collision protectors.

We also supply labels and offer additional services, including industrial cleaning, equipment assembly and maintenance, and recruitment support. If you need a comprehensive package to fit your needs, ask as about our project management services.

Our ability to hit tight deadlines while maintaining the highest standards of safety and quality has seen us become the trusted partner of some of the biggest and best-known companies in the world, covering sectors including agriculture, automotive, e-commerce, wholesale, and more.

Contact us for more information.