Labels are indispensable in any warehousing company or distribution center to quickly identify and access products. For this reason, it is necessary to implement labeling systems for warehouses, from the design to the production and placement of labels.

Warehouse labeling systems are essential for warehouses to operate efficiently and productively. Knowing the exact location of stored materials saves time, streamlines processes and allows for a greater flow of goods.

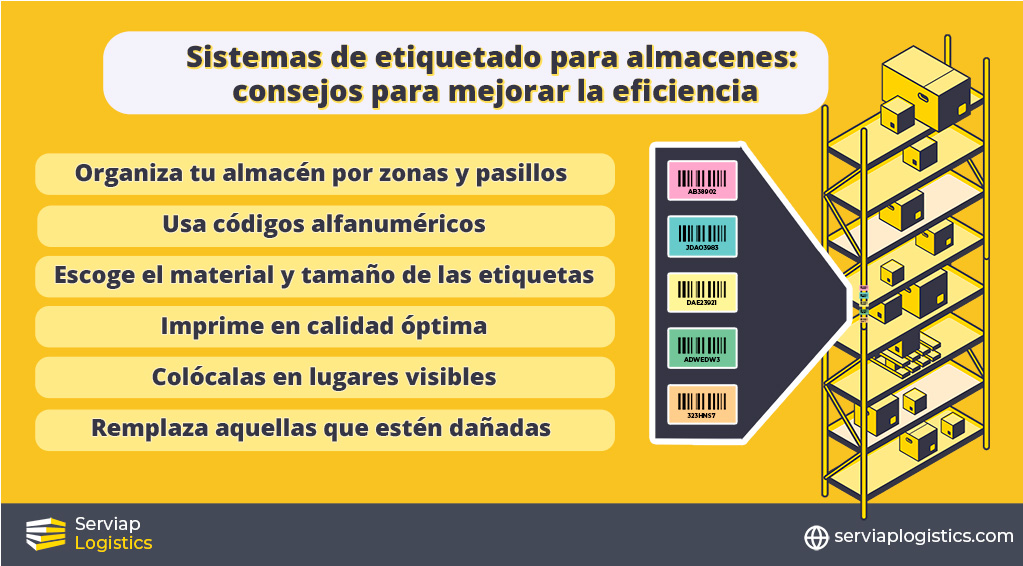

Warehouse labeling systems take into account several factors, from the material and size of the labels to their location and the organization of the information. In addition, labels must not be easy to peel, smudge or erase, and the data they contain must be easy to read or scan.

SEE ALSO: Warehouse Installation Checklist: 7 Important Things to Get Right

As with many warehouse projects, engaging the services of a warehouse installation consultant will help in choosing the best warehouse labeling systems. These experts will develop an accurate plan that can be tailored to the needs within the facility and work in harmony with the types of warehouse security signage.

Warehouse labeling systems can be organized by type of label (removable, permanent, hanging, retroreflective, etc.), by specific situations (use of cold storage and outdoor labels) and by placement, which is explained below.

Serviap Logistics provides warehouse labeling services in Brazil, the United States and Mexico. If you need more information contact us at.

Aspects to be taken into account in warehouse labeling systems

Before implementing one of the warehouse labeling systems, remember that the labels must have a combination of numbers and letters in sequential order. This code should also be intuitive for users, such as starting with the letter A and the number 0, for example, and so on.

Labels should be easy to find and read, whether on aisles, shelves, products or floors. If necessary, you can also place arrows to guide staff attention to the location of labels.

It is also essential that label placement be uniform, follow a consistent and organized positioning plan, and be homogeneous in terms of materials, fonts and colors. Finally, you will need to consider the label attachment system: plastic supports, direct application by means of stickers, etc.

Warehouse labeling systems: placement

Aisles

Aisle labels are an essential part of the organization of a warehouse or distribution center, as they help identify aisles and give indications, such as direction of flow or emergency exits.

This labeling is based on a numbering or sequence of characters. The panels are usually fixed with double-sided adhesive pads or screws on shelves, at the beginning of aisles and at the top so that they are not damaged by machinery such as forklifts. They can also be hung from the ceiling.

The most commonly used materials are PVC, but they can also be manufactured with any other support that can withstand high temperatures or exposure to corrosive materials. In terms of size, they can be 12 x 12 inches when they have a single letter or number or 12 x 16-18 inches when the signs have more than one character.

On-shelf labeling systems

In order to label the shelving in a warehouse, it is first necessary to define the method of identification of this storage equipment, which is usually distributed by units or sections, depending on the type of goods and materials stored.

Two ways of labeling shelves within a warehouse are standard and serpentine. With the former, products are labeled in a parallel structure and in a sequential manner. With the serpentine method, pickers can zigzag to pick products from one side of the aisle to the other.

In addition, shelves will be labeled from bottom to top, such as 01, 02, 03, etc., down to the last row of that unit or section. Labels are usually up to ten centimeters wide and are printed in various colors and materials, although the most common labels have a magnetic metal backing.

SEE ALSO: Warehouse floor markings: 4 very important considerations

Warehouse labeling systems for individual products

When new products arrive at a warehouse, they must be labeled and coded in the receiving area. This process helps to obtain information about the type of item, the number of units that make up its lot and other characteristics that facilitate its handling.

Individual labels can be of different types. For example, there are content labels, which usually carry a barcode and a description of the goods; handling instructions, especially for sensitive or hazardous materials; and origin and destination labels.

Label printers are used in warehouses and distribution centers to label products quickly. These labels are self-adhesive, are sized according to the type of product and are usually white and printed with black ink, although they can also be in other colors.

Floor mounted warehouse labeling systems

Floor labeling and marking provides important information within the warehouse, such as pedestrian or machinery passage, receiving and distribution areas, circulation within the warehouse and hazardous areas.

Floor labels can be printed on high quality self-adhesive material. However, they can also have protections, such as an aluminum frame and a transparent cover, to extend their service life, and are sometimes made of metal and screwed to the floor.

Floor labels contain alphanumeric bar codes and other data that help identify a lot or unit of merchandise. Sizes and colors vary depending on the organization within the warehouse, but should be visible enough to attract attention.

The importance of labeling systems

The correct placement of labels, as one of the labeling systems in warehouses, minimizes storage errors because, with clear coding, it is easier to locate products and move them to other areas of the store, which also aids shipping speed.

Another advantage is the traceability of the goods within the warehouse or distribution center, because when the aisles, shelves and the products themselves are labeled, it is easier to know where they are in the distribution process, whether they have just arrived or whether they have been stored for some time and are waiting to be distributed.

The implementation of warehouse labeling systems improves the flow of goods, streamlines processes and increases the productivity rate of the facilities.

Serviap Logistics offers labeling services for warehouses

At Serviap Logistics we offer warehouse labeling systems to suit the needs of your warehousing business and distribution centers, whether in Brazil, Mexico or the United States.

We can also help you with signage, floor marking, supply and installation of anti-collision barriers and equipment assembly. In addition, we provide project management services and oversee the installation, refurbishment or relocation of a warehouse from start to finish.

Some of the world’s largest companies have relied on the quality of our services and our attention to detail; they come from sectors as varied as automotive, e-commerce and wholesale, among others. Wherever we work, we meet the highest safety standards, including OSHA certification in the United States.

If you want to be another one of our satisfied customers, contact us at. And if you were interested in this article on warehouse labeling systems, read the rest of our coverage.