Table of Contents

An efficient warehouse guardrail system is essential within your logistics facility. Along with other measures, guardrails provide both physical and visual barriers to diminish damage from impact and vehicle accidents and delineate areas.

Warehouse guardrails, pallet racks, bollards, and additional warehouse protection barriers enhance safety measures for personnel, equipment, and infrastructure. For employees operating vehicles, it is imperative to have marked, above-ground indicators that are visible and secure.

Depending on your needs, there are many different types of guardrails to choose from. They need to be selected and installed properly, so that legal compliance and durability are guaranteed, complementing the Personal Protection Equipment (PPE) protocols.

At Serviap Logistics, we supply and install warehouse guardrails in Brazil, Mexico, and the United States. Contact us today to find out more.

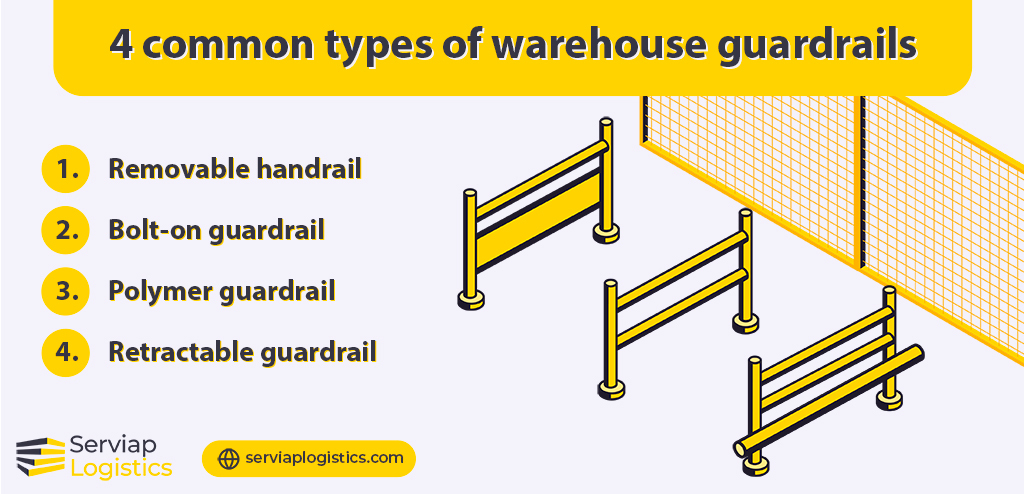

4 types of warehouse guardrails

If you’re working on the safety of your warehouse project management, learning about the most common options for warehouse guardrails can help you achieve a more adequate system.

Removable handrail

The removable handrail is a type of warehouse guardrail that is commonly used to separate areas in need of easy but not constant access. This rail is removable between posts. It can be easily stored, placed, and cleaned. Also, it is lighter than other heavy-duty warehouse guardrails, so it is flexible but won’t absorb high-level impact.

Bolt-on steel guardrail

The steel warehouse guardrail is the most traditional option. It helps prevent forklifts, sweepers, and other vehicles from damaging your facility and equipment or injuring employees. It is ideal in situations where rigid, durable protection is needed because it can successfully protect workers from serious accidents, as it was created for roads and highways.

Polymer warehouse guardrail

The polymer barriers serve as a broad alternative to steel warehouse guardrails. Made from impact-modified polypropylene, they are rated and tested to absorb small-duty impacts to heavier damage. Compared to steel, they are more durable, standardized, and eliminate impact shock, which makes them cost-effective in the long run. However, bear in mind that initial investment can be higher.

Retractable warehouse guardrail

The retractable guardrails are a heavy-duty safety system that isn’t fully removable but can be retracted to allow access to certain areas when needed. They are ideal for both indoor and outdoor areas that need high-level protection with variable access points. This warehouse guardrail is usually made of steel, with a design that is lift-assisted and locks up and down.

Other safety barriers for additional protection

Warehouse guardrails can be complemented with a series of other safety barriers to design dynamic protection for your facility.

Column protectors

They safeguard columns from forklift or machinery collisions, preventing potential damage. To this end, various protective equipment options are available, featuring different materials and shapes to mitigate impact damage. These materials can be categorized as either hard or flexible, with the selection depending on individual store requirements.

Safety gates

They offer controlled access to specific areas and are particularly valuable for preventing unauthorized entry to loading bays when not in use, as well as managing the flow of people and vehicles to avoid accidents. In operations dealing with substantial incoming and outgoing goods or experiencing significant traffic, safety gates become critical components alongside warehouse guardrails.

Bollards

Warehouse bollards are short posts that offer protection to doorways and supporting beams from impact. Buried bollards, typically made of stone or metal, provide exceptional impact resistance but are permanent fixtures. For a more flexible alternative, there are bollards made with materials like high-density foam that cushion impacts and return to their original shape.

Retractable barriers

They are versatile temporary dividers designed for on-demand use. Typically composed of sturdy material, they can be easily clipped into place to separate or divide areas. Retractable barriers are commonly employed to isolate aisles or other spaces, preventing the proximity of people and vehicles. Unlike a retractable warehouse guardrail, this option lacks impact protection.

The importance of your warehouse guardrail system

Protection for your facility is a critical step in setting up a warehouse, as it will save you time and money and keep everyone safer. Warehouse guardrails create a good safety barrier for infrastructure, protecting columns, walls, and other installations. Besides, an efficient warehouse guardrail system is a key element in diminishing possible damage from accidents and hazards, such as fire emergencies.

Furthermore, warehouse guardrails help reduce handling errors. They can can assist you in better controlling the process and restricting areas, optimizing transit, and preventing loss of goods, as products are frequently moved from one place to another. This way, you ensure that products are handled without breaking, spilling, denting, or suffering from other damage.

Still, one of the main reasons for efficient warehouse guardrail applications is to protect employees. The guardrails are usually present in many dangerous places already known to the work team, but they also serve to warn of temporary and variable risks. A large proportion of warehouse accidents involve human error, which makes the care of employees very important.

This is fundamental for maintaining legal compliance with safety regulations as well. According to OSHA, the Occupational Safety and Health Administration in the US, some of the leading causes of workers’ accidents involve fall protection, hazard communication, and machinery guarding. To keep these from happening, proper guardrailing is needed in any effective warehouse.

How to install warehouse guardrails

The first step is to outline the needs of your space, as warehouse guardrails can serve different purposes in the same facility, according to the flow of your operations. You may need to set up combinations between different guardrails, accompanied by other options for safety barriers.

It’s important to check the material quality of the safety guardrails, preferring products that are tested in compliance with protection standards. For warehouse guardrail systems, the most common concern is choosing between steel and polymer. Both of the options help you meet legal requirements, but all can be compromised if there isn’t proper planning.

Thus, investigate the correct installing of all security barriers. Analyze the proper height, spacing, and quality of application. Map out the warehouse operations and ensure that the equipment is well distributed according to the needs of each area. You can hire a warehouse setup consultant to assess your space, in case you are having trouble organizing your operations.

Professional assistance can help you guarantee that your safety system runs smoothly and efficiently from the get-go. Additionally, don’t forget to perform periodic inspections to monitor the functionality and usage of the warehouse guardrails, as well as to analyze the lifespan of the materials.

Serviap Logistics provides warehouse guardrail assistance

At Serviap Logistics, we can support you with warehouse guardrail installation, along with safety barrier planning. We operate in Brazil, Mexico, and the United States, and our services are always delivered in full compliance with local regulations.

As well as warehouse guardrails, we distribute and install racking, signage, floor marking, and other collision protection, as well as supplying labels and providing industrial cleaning services. We also offer project management services to oversee the setup, refit, or relocation of a facility from start to finish.

Thanks to our ability to hit tight deadlines without sacrificing quality or safety, we are the preferred partner of some of the biggest and best known companies in the world, covering a range of industries including automotive, e-commerce, and wholesale, among others.

Contact us today to find out more about how we can assist you.