Señalización de suelos de almacenes es una pieza fundamental de la infraestructura de almacenes y centros de distribución, que en la mayoría de los países están sujetos a normativas estrictas.

Esto significa que comprender y cumplir las directrices de señalización de suelos del almacén suele ser esencial para evitar problemas de cumplimiento y complicaciones legales cuando se inspeccionan, así como para mantener la seguridad y la eficacia en las instalaciones.

Dependiendo del país en el que opere, su centro deberá seguir las directrices locales, que suelen ser similares entre los distintos países, pero también suelen incluir algunas diferencias y partiocularidades importantes. Por eso es importante conocer a fondo las normas con las que hay que trabajar.

Por este motivo, muchos gerentes optan por trabajar con proveedores experimentados, que conocen a la perfección las directrices de señalización de suelos del almacén aplicables en la jurisdicción en la que trabajan y, por tanto, pueden garantizar que todo lo que se instale en su espacio cumplirá plenamente la normativa.

Ponte en contacto con nosotros si buscas un socio para instalar la señalización de suelos de almacenes en Brasil, México o Estados Unidos.

¿Qué son las señalizaciones de suelos de los almacenes?

La señalización de suelos de almacenes se utiliza en centros logísticos y de distribución para separar distintas zonas, indicar pasillos de tránsito y, en general, mejorar la seguridad, la eficacia y la organización. Las directrices de señalización de suelos del almacén variarán en función de los colores utilizados y las dimensiones de las líneas instaladas.

Entre las marcas habituales en el suelo se incluyen las marcas de pasillos, las marcas de muelles de carga, las zonas de seguridad, las zonas de materiales peligrosos, las marcas de áreas de almacenamiento, las zonas de preparación de pedidos y embalaje, y los puntos de cruce. Las directrices de señalización de suelos del almacén dictan los parámetros dentro de los cuales deben colocarse dichas marcas, con el fin de normalizar

Evidentemente, las marcas en el suelo deben ser duraderas y suelen pintarse o aplicarse con pintura especializada. El tipo que más le convenga dependerá de su duración, de lo pronto o a menudo que cambien las marcas y de su presupuesto para instalarlas.

Marcas en el suelo con cinta adhesiva

Las marcas de cinta se utilizan ampliamente en almacenes de todo el mundo. El uso de cinta de alta visibilidad ayuda a delimitar claramente los pasillos, las zonas peligrosas y los pasos de peatones. Además de cintas de distintos colores, también existen otros tipos que pueden ser necesarios, como cintas reflectantes para aumentar la visibilidad o cintas de congelación, fabricadas específicamente para almacenes frigoríficos.

Entre las ventajas de utilizar cinta adhesiva se encuentran su rentabilidad en comparación con las líneas pintadas, la rapidez con la que se pueden utilizar las zonas con marcas grabadas -que es casi inmediata tras su colocación- y la versatilidad de la señalización de suelos con cinta adhesiva, que puede retirarse fácilmente para adaptarse a las modificaciones del flujo de trabajo.

Sin embargo, el uso de cinta adhesiva puede presentar algunos inconvenientes, ya que es menos duradera que la pintura y, por tanto, puede ser necesario sustituirla antes. Además, la cinta adhesiva puede ser más difícil de mantener tan limpia como la pintura, aunque contratar servicios periódicos de limpieza de naves industriales debería ayudar a mantenerla.

Revestimiento de pintura epoxi

Las marcas de suelo con pintura epoxídica son una opción extremadamente duradera, adecuada para su uso en líneas destinadas a permanecer a largo plazo. La resistencia de esta pintura especializada le permite soportar un tráfico intenso y regular sin degradarse.

Las marcas de pintura epoxi para suelos también son fáciles de limpiar y, en caso de desgaste, basta con retocarlas para devolverlas a su estado original.

Obviamente, este tipo de señalización tiene un coste superior al de la cinta adhesiva, pero la inversión inicial se verá compensada por el hecho de que durará mucho más. Su colocación también requerirá, obviamente, que las zonas queden fuera de uso mientras se seca, por lo que suele ser aconsejable instalarlo durante el montaje del almacén.

Cinta de peinar y pintura

La instalación de marcas en el suelo no tiene por qué ser una elección directa entre cinta adhesiva y pintura, ya que puede descubrir que lo más adecuado es combinarlas. Para las marcas que se sabe que van a ser necesarias a largo plazo, la pintura puede ser ideal. Mientras que para las que puedan estar sujetas a cambios periódicos en función del flujo de trabajo, puede utilizarse cinta adhesiva.

Eso también representará un término medio en términos de presupuesto, en caso de que eso sea un facotr en su toma de decisiones. Si deseas combinar cinta adhesiva y pintura, es importante que contrates a un proveedor con experiencia en ambas técnicas.

Aunque muchos proveedores ofrecen ambos servicios, algunos se especializan o tienen más experiencia con uno u otro método.

Directrices de señalización de suelos del almacénen Brasil, México y Estados Unidos

Lasdirectrices de señalización de suelos del almacén varían de un país a otro, por lo que, si va a ampliar una empresa de logística a una nueva jurisdicción, tendrá que garantizar el cumplimiento de las normas locales.

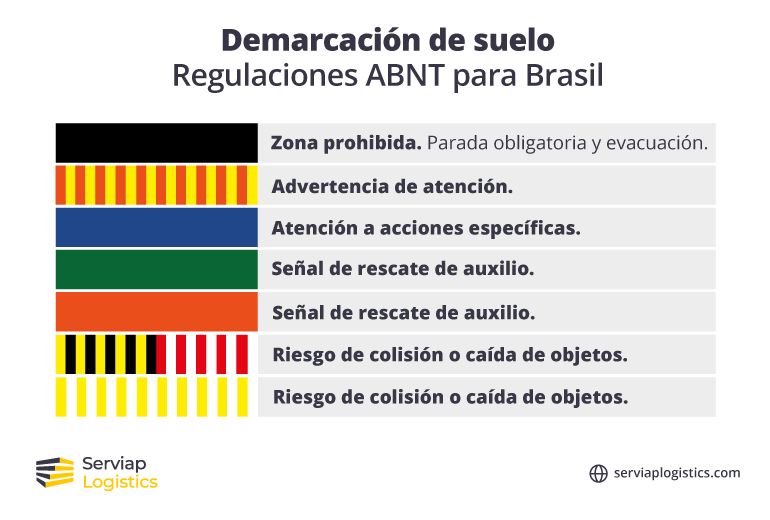

La demarcación del suelo de los almacenes en Brasil debe cumplir las normas establecidas por la Organización Nacional de Normalización Industrial (ABNT). Las directrices de señalización de suelos del almacén deben cumplir las normas NR 26, que establecen directrices específicas para los colores y la señalización de seguridad.

Esta normativa tiene por objeto crear un enfoque normalizado de las marcas de seguridad, garantizando que todos los almacenes de Brasil mantengan un sistema coherente y reconocible.

En México, la Ley Federal sobre Metrología y Normalización(pdf) es un conjunto de normas clave para la industria del almacenamiento. Las normas de seguridad están señaladas en las NOM-001-STPS y NOM-026-STPS, que detallan los requisitos de señalización de seguridad en los centros de trabajo.

Las normas son aplicables en todo el país y recogen las obligaciones de empresarios y personal, entre otros puntos. El cumplimiento de esta normativa no sólo garantiza la conformidad, sino que también contribuye a crear un entorno más seguro para los empleados.

Mientras tanto, en Estados Unidos, la Administración de Seguridad y Salud en el Trabajo(OSHA) desempeña un papel fundamental en el establecimiento de normas de seguridad en el lugar de trabajo, y las directrices de la OSHA suelen servir también como norma general en algunos otros países.

Las directrices de señalización de suelos del almacén se abordan especialmente en la norma 29 CFR 1910.144, que ofrece una orientación exhaustiva sobre el uso de colores para las marcas de seguridad. El sistema de codificación por colores de la OSHA ayuda a transmitir rápidamente información sobre peligros potenciales, contribuyendo a prevenir accidentes y lesiones.

Garantizar la correcta instalación de marcas en el suelo

Los instaladores cualificados pueden aportar su experiencia para ayudarte con la instalación y garantizarle que cumple todas las directrices de señalización de suelos del almacén. También pueden asesorarte sobre su plano de señalización y sugerirte mejoras o modificaciones para adaptarlo mejor a sus necesidades.

Un proveedor experimentado tendrá los conocimientos necesarios para utilizar equipos especializados y evitar cualquier percance durante la instalación, y también podrá ayudarte con futuras modificaciones e inspecciones.

A menudo, un proveedor de señalización de suelos para almacenes también ofrecerá servicios relacionados adicionales, que podrían ser especialmente útiles si está instalando la demarcación durante un montaje, una reforma o un traslado.

Por otra parte, aunque sólo necesite ayuda para instalar la señalización de suelos, un proveedor con una amplia cartera de servicios podría resultarle útil más adelante en otros aspectos, por lo que lo ideal es tener en mente sus planes futuros a la hora de contratar servicios de señalización de suelos.

Serviap Logistics ofrece servicios de marcaje de suelos de almacén

En Serviap Logistics prestamos e instalamos servicios de optimización de almacenes en Brasil, México y Estados Unidos. Entre ellas se incluye la señalización de suelos, que siempre instalamos cumpliendo plenamente las directrices de señalización de suelos del almacén.

También proporcionamos e instalamos estanterías, protección contra colisiones y señalización, además de suministrar etiquetas y ofrecer servicios de limpieza industrial, mientras que nuestros servicios de gestión de proyectos de almacén incluyen un paquete completo de servicios para ayudarle con la instalación, remodelación o reubicación de principio a fin.

Nuestro compromiso con la excelencia y nuestra capacidad para cumplir plazos ajustados son bien conocidos entre nuestros clientes, entre los que figuran algunas de las empresas más grandes y conocidas del mundo, que abarcan una amplia gama de sectores, como la agricultura, la automoción, el comercio electrónico y la venta al por mayor.

Ponte en contacto con nosotros hoy mismo para saber más sobre cómo podemos ayudarle.