Setting up or refitting a warehouse or distribution center requires careful planning and the right equipment for the work that will be done. So understanding which warehouse equipment solutions are best for you will depend on your needs.

Key considerations include the facility conditions, the budget available, the size of staff, as well as the type of goods and assets handled. With that in mind, it becomes easier to follow a warehouse setup checklist to make sure everything is in order.

In this process, you must guarantee everything complies with local warehouse safety standards, so that you avoid legal issues or financial penalties, and, most importantly, create a safer workplace for equipment and workers. To help you with that, you can always count on the assistance of professional consultants that will provide you with expert insight.

Contact us to learn more about the best warehouse equipment solutions for your operations.

The importance of warehouse design management

Proper design and setup can help you achieve better flow of goods, personnel, and warehouse equipment solutions, as well as space optimization and higher productivity. You need to consider how assets and operations interact, and also how to keep them durable, efficient, and safe.

Secondly, it is important to analyze the nature of the goods being handled, considering the personnel and machinery involved, because these factors will tell you which warehouse equipment solutions are best for you. It will also make it easier to control operations and have an efficient plan for scalability and adaptability.

In this scenario, implementing warehouse safety standards minimizes risks. Safeguarding both employees and assets is essential in any warehouse, given the handling of diverse or delicate goods, the use of heavy machinery, and the presence of hazardous areas or substances. Warehouse equipment solutions accordingly take this into account.

So it is imperative to follow regulatory compliance in all stages of a warehouse setup checklist. You must navigate different standards according to the region you work in, such as the OSHA for the US, the Brazilian Health Regulatory Agency in Brazil, or the Secretariat of Labor and Social Welfare in Mexico. Luckily, you can always collaborate with professionals to guarantee conformity in faster ways.

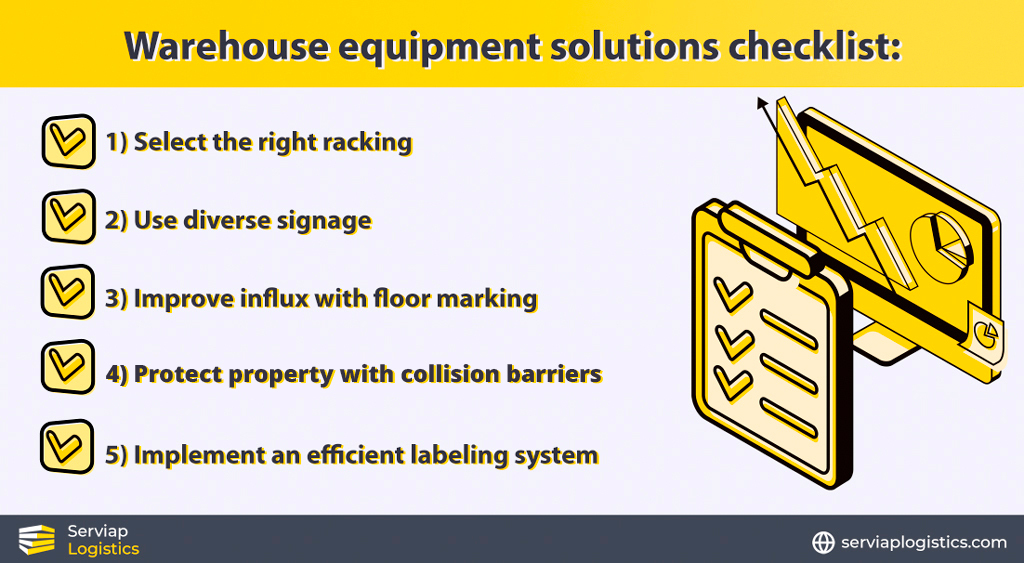

Warehouse equipment solutions checklist: 5 key elements

To help you deal with the many elements a logistics operation requires, you should create a checklist with 5 common warehouse equipment solutions that can enhance the setup and management of your facility.

1) Select the right racking

If you want to improve organization and maximize storage space, accurate warehouse racking installation is necessary. Good pallet racking systems allow for proper vertical storage and improve the warehouse layout. To select the right type, you should plan your stacking pattern, distribute the weight evenly, and use lifting equipment to prevent injuries and perform the racking work quickly and safely.

It is crucial to take into consideration what types of products will be stored, so you can plan how many racks are needed, as well as how they will be arranged. Other aspects include whether the warehouse is indoors or outdoors, and the special equipment you may need when installing or dismantling racking shelves.

Remember that each facility requires different warehouse equipment solutions in racking. For example, taller buildings allow for higher storage racks. However, forklifts and other equipment may not be able to reach taller heights, so optimization can be compromised, and you may be facing extra costs in having to buy new machinery. So don’t forget to study the facility conditions closely.

2) Use diverse signage

Signs can improve security in a warehouse greatly. Safety signage is used to warn personnel of potential risks, delicate areas, or exit routes. They can be placed in loading and unloading areas to optimize forklift and heavy vehicle traffic, as well as to mark loading capacities and prevent falling objects or other workplace accidents.

Beyond security, signage also plays an important part in organizing. Aisle and hanging signs guide people to know exactly where goods are located. Signage with logo can reinforce the company’s image indoors, and help first-time arrivals to better identify the warehouse’s entrance when applied outside of the building.

Additionally, barcode signs are a great solution for keeping track of inventory. The QR barcodes are placed in many locations, such as on racks, aisles, or on the products. Along with other labels, you can also use barcode signage for added accessibility and visibility. So, signage is a flexible option available for optimizing your warehouse.

3) Improve influx with floor marking

Floor marks help delimit different work areas and provide clear directions for traffic throughout the warehouse. This way, they reinforce safety signs and also improve operations efficiency. They will often follow patterns and color codes to guarantee the easiest visual guidance.

One of the most common options for floor marking is adhesive materials. There are many types of floor marking tape to choose from, and they generally are very easy to apply, fix and edit. The durability will depend on the right application, the chosen tape materials, and aftercare.

A usual alternative to tapes in epoxy paint. It is more long-lasting, customizable, and resistant than floor marking tapes, but may take require more money and time to apply. Both methods can greatly improve daily work-life and contribute to more accurate traffic and procedures. So, either way, don’t forget to include floor marking in your warehouse equipment solutions checklist.

4) Protect property with collision barriers

Protection barriers are fundamental to assure the operational safety of a warehouse. They are a physical addition to protect items, personnel, equipment, and infrastructure. They can offer a vast range of safety and different uses, so it’s important to be clear about your needs.

Bollards, for example, are often installed to protect doorways and minimize impacts. Meanwhile, column protectors can save walls and columns from machinery and equipment collision. There are also guard rails and safety gates to delimit, separate, and protect areas within a warehouse.

The advantage of using a variety of collision barriers is that you can create a dynamic system for preventing accidents, complying with local regulations, and safeguarding lives. However, it’s crucial to make sure that they are all well placed, following distance and installation regulations. Also, make regular inspections to continuously ensure high-quality safety over time.

5) Implement an efficient labeling system

Labels help you quickly identify and access products. They are one of the most common and cost-efficient warehouse equipment solutions for operations that want to improve productivity. Labeling systems should consider many factors, from the type and size of the tags to where they’ll be applied and how the information will be organized.

You can use labels on shelves, items, aisles, or even on the floor. They can be removable or permanent, opaque or reflective. Overall, there are many ways of labeling, that will depend mainly on the type of goods stored and the size of operations. An efficient combination of labels should be planned early on to improve durability.

Thus, when implementing a warehouse labeling system, it’s important to follow codes that are user-friendly and intuitive, so staff can handle them easily. The labels should be placed in a uniformed positioning plan, using the same materials, fonts, and colors. These details minimize storage errors and help with dispatch speed.

Improve your warehouse setup with experts

Equipment management can be a very complex step in warehouse setup. It involves many operational items, such as workstations, machinery, shelving, racks, collision protectors, and more. The proper placement and assembly affect the efficiency of warehouse equipment solutions. This is why collaborating with professional consultants can save you a lot of time and money.

They will adapt your budget to set everything up correctly from the start. With experience, they perform equipment installation in an assigned time and make sure that the initial assembly or dismantling is carried out smoothly. This is vital to ensure speed and safety, as well as give you expert insight on any areas that can be improved.

Over time, you also need periodic inspections to identify possible deficiencies, optimize space, and improve the lifetime of equipment installed. It’s completely normal for assets to deteriorate, so inspecting them guarantees that your operations are safe and up to date. For this, you should count on professional inspectors to prevent inconveniences and additional expenses that can come with inaccurate checkups.

You can hire professionals directly, or collaborate with a warehouse setup company that can better understand your needs and quickly find the best experts according to your region, budget, and operations. Remember that proper installation and inspection are key to boosting your warehouse equipment solutions and maintaining them efficient for as long as possible.

Serviap Logistics offers warehouse setup solutions

At Serviap Logistics, we can assist you with warehouse setup services in Brazil, Mexico, and the United States.

Our services include providing and installing collision protectors, signage, and floor marking, as well as the design and supply of labels, and project management services to oversee a warehouse setup, refit, or relocation from start to finish.

Our ability to hit tight deadlines without sacrificing quality or safety has helped us become the trusted partner of some of the largest and best-known companies in the world, covering industries such as automotive, ecommerce, and wholesale.

Contact us to find out more about how we can assist you.

If you were interested in this article about warehouse equipment solutions, Read more of our coverage.