Working with a professional for warehouse equipment installation can be crucial to ensure that your warehousing or distribution business runs safely and smoothly.

Whether you are just starting out or upgrading your facility, having a professional install shelving, signage and floor marking will allow you to focus on the operational side of your business and enjoy peace of mind knowing that your warehouse equipment installation has been done correctly.

Anyone working in warehousing, logistics or production knows that setting up a warehouse or distribution center requires a lot of planning. While efficiency and productivity will obviously be key concerns, so will safety.

One of the advantages of having professionals oversee the installation of your warehouse equipment is knowing that all of these concerns will be taken into account.

Because a professional will be accustomed to working to the highest safety standards wherever he or she works, such as those set by the Occupational Safety and Health Administration (OSHA) in the United States.

For those looking for more comprehensive assistance, warehouse equipment installation can also be part of a broader warehouse project management service. The supplier will also provide guidance on the layout and organization of the facility according to your operational needs.

At Serviap Logistics we offer warehouse assembly services in Brazil, Mexico and the United States. Contact us at for more information.

Installation of warehouse equipment for key infrastructure

The installation of warehouse equipment for key infrastructure may include the installation of any of the following:

Shelving

Warehouse racks are a crucial part of almost any warehouse or distribution center. While some types of warehouse racking can be relatively simple, others can be very complex equipment with moving and electrical parts.

As such, racking is a critical piece of infrastructure that a warehouse equipment installation service should cover. If your equipment installation is part of a project management and configuration service, your supplier will also be able to guide you on what types of racks to install.

This decision will take into account the people, goods and machinery that will circulate through the area when it is in operation, as well as the size and layout of the facility.

Floor marking

Warehouse floor signage is another element that almost no facility will do without, often being crucial to maintaining safety, flow, productivity and high efficiency in daily operation. Generally, any warehouse equipment installation provider will offer this service.

There are two main types of warehouse floor marking to choose from: masking tape or epoxy paint, and the choice of the one that best suits your needs will depend on how permanent you want it to be and how strong you need it to be.

Tape is cheaper and quicker to apply and remove, so it offers more flexibility if you think you may change your warehouse configuration in the future. Meanwhile, paint is more expensive and permanent, but also more durable, as it can withstand heavier traffic flows.

Signage

Another critical element of a facility, which a warehouse equipment installation provider will also cover, is signage.

There are many different types of warehouse signage to choose from, depending on your needs, such as safety signs, aisle signs, dock door signs and load capacity signs.

Warehouse signage should always be of a size and color appropriate for its use and installed where it can be easily seen, especially when its purpose is safety related.

Protective barriers

Warehouse protection barriers ensure the safety of people and protect equipment and facilities from unnecessary damage. This can be especially important when there is a significant flow of heavy goods and vehicles, such as forklifts, in motion.

The complexity of collision protection installation will depend on the type being installed. In some cases, bollards and barriers will be sunk deep into the ground.

Given the importance of protective barriers, it is always recommended to hire a professional to provide guidance on which ones to place and where, as well as their installation.

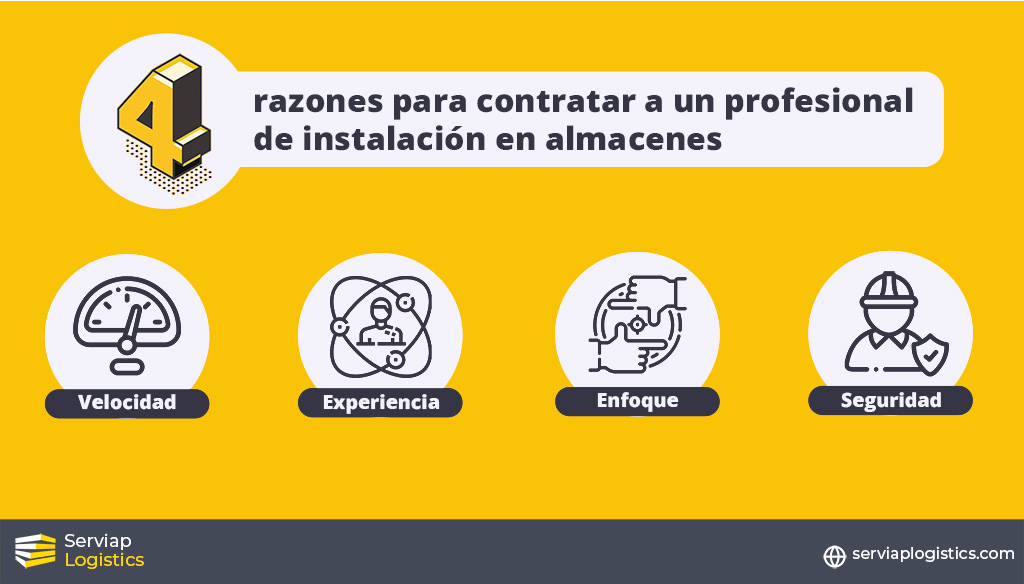

4 reasons to hire a professional warehouse equipment installer

Hiring professionals to install your warehouse equipment offers a number of advantages:

1) Speed

When setting up or remodeling a facility, it is always important to establish start and finish dates before installing warehouse equipment. This planning is critical to ensure that subsequent activities can be properly planned, so it is important to hire a supplier that can work quickly and meet deadlines.

2) Experience

Warehouse equipment installation is best done by an experienced professional who knows exactly what he or she is doing. Such a supplier will not only be able to install the equipment quickly, but also to anticipate potential problems with an installation before they arise, as well as draw on their expertise to overcome any unexpected obstacles or setbacks during the installation process.

3) Focus

As mentioned above, leaving the installation of warehouse equipment to an expert allows you to focus on other aspects of your business. This can be especially important if you are setting up a warehouse or distribution center for the first time, or moving a facility, as it frees you to focus on making sure that everything you will need to get up and running once the installation is complete is taken care of.

4) Security

Ensuring safety is at the heart of every aspect of the warehouse installation process, and your key infrastructure is of particular importance in eliminating and mitigating potential risks. Therefore, by entrusting the installation of your warehouse equipment to a professional, you can be assured that all relevant regulations and safety issues are taken into account.

Safety standards associated with the installation of warehouse equipment

The installation of warehouse equipment must be performed in accordance with the legal safety standards applicable at the location of the facility. In the case of the United States, some of the standards established and enforced by OSHA will affect the installation of warehouse equipment.

Although standards in other countries vary, they are often quite similar, and the OSHA standard is often considered best practice in many places where regulations are not as stringent.

So if you’re hiring a warehouse equipment installation provider, you’ll want to make sure they are OSHA certified if operating in the U.S., or familiar with the relevant standards in any other country.

Serviap Logistics provides installation of warehouse equipment

At Serviap Logistics we provide warehouse equipment installation in Brazil, Mexico and the United States.

Our installation services include racking, signage, floor marking and collision protection. We also supply labels and offer project management services to oversee the installation, remodeling or relocation of a warehouse from start to finish.

We count some of the world’s largest companies among our satisfied customers and partners, covering a wide range of industries such as automotive, e-commerce, wholesale and others.

As a family business that has grown internationally after starting in Mexico, we are committed to service excellence and pride ourselves in offering personalized service to every customer.

We are also dedicated to maintaining the highest safety standards wherever we operate, including OSHA certification in the United States.

Contact us at today for more information on how we can help you with warehouse equipment installation.