Table of Contents

In warehousing, pallets play a pivotal role in ensuring efficient operations. Choosing the right types of pallets is crucial for maximizing storage space and maintaining a streamlined workflow.

Each type offers unique advantages tailored to specific operational requirements. Whether you prioritize accessibility, space efficiency, or specialized storage needs, there is a pallet racking system to suit your facility. Knowing how to stack a pallet rack properly will also help.

It’s essential to assess your specific needs, considering factors such as product type, turnover rate, available space, and budget constraints. By making an informed choice, you can optimize your warehouse or distribution center for maximum efficiency and productivity.

Contact us if you need pallet racking services.

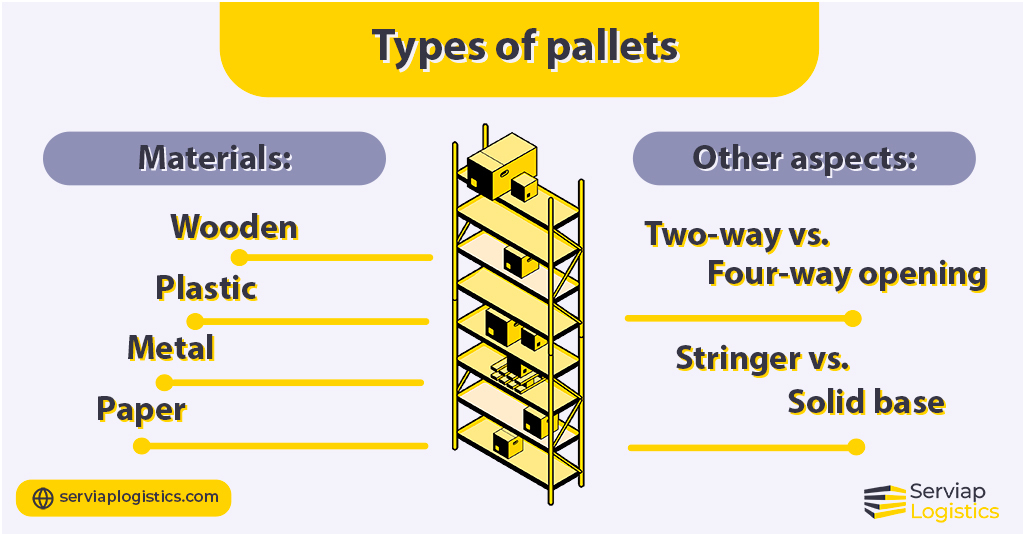

Types of pallets: 4 different materials

When it comes to selecting different types of pallets, material plays an important part. Whichever you choose will affect performance factors including durability, weight capacity, and usefulness for distinct applications.

1) Wooden pallets

Wooden pallets are by far the most used types of pallets in warehouses.

They are favored for their availability, cost-effectiveness, and ease of repair. In fact, the wooden pallet market is still growing in many regions, driven by the logistics and transportation industry, according to FMI.

However, the weight varies greatly based on the type of wood used. Some other drawbacks are the risk of moisture damage as well as lower durability for long-distance transportation between warehouses or other destinations. If you’re shipping lighter products, you may be able to save costs by going with softwood pallets.

2) Plastic pallets

Plastic pallets have gained popularity due to their durability. They are widely used in industries where cleanliness and resistance to moisture are crucial, such as beverages, pharmaceuticals, or other liquid goods that are prone to spilling. They are generally uniform in weight as well as resistant to wear, weather, and pests.

On the other hand, these types of pallets tend to have a higher upfront cost compared to wooden options. While they are durable and do not splinter, plastic pallets are more challenging to repair than wooden ones. Additionally, managers should research eco-friendly options, as some are not biodegradable and can contribute to plastic waste.

3) Metal pallets

When it comes to sheer strength, metal pallets are the most suitable for heavy-duty applications. They are commonly found in the automotive industry and other sectors that deal with metal processing. Often, steel pallets follow the same guidelines as their wooden counterparts, which allows them to fit in standard warehouse racking.

Beyond the long lifespan and high load capacity, metal pallets are non-flammable, making them a great choice for industries where fire safety standards are critical. However, they are considerably heavier and more costly than wooden or plastic pallets. They are also subsceptible to rust.

4) Paper pallets

Paper pallets are a lightweight and eco-friendly alternative to traditional materials. They are typically made of cardboard and used for lighter loads and one-time shipping applications. Their lightweight aspect can reduce shipping costs, while also being highly customizable to fit specific dimensions and load requirements.

These types of pallets are often made from recycled materials and are fully recyclable after use, but, just like wooden pallets, they can become weak and unstable if exposed to moisture. Furthermore, they are not suitable for heavy or bulky items and have lower load capacities compared to other materials.

Different aspects and pallet styles

There is a wide variety of pallet options in size, design, and functionality. Among the common types of pallets, the open deck pallet stands out, characterized by its surface with a grid or mesh pattern of openings. These pallets tend to be cost-effective and lightweight, making them easier to transport.

When selecting the open deck style, you can also choose between two-way and four-way pallets. One has forklift openings on just two ends, whereas the latter has four, ensuring accessibility from all sides. This decision is crucial as it affects transportation according to the machinery available, such as forklifts or pallet jacks.

Another consideration when selecting different types of pallets is whether to opt for a solid block or a stringer base. Both are capable of supporting variable loads, but block pallets are generally more robust. This increased strength comes at a financial cost, though.

Alternative to open deck pallets, there are those with a closed deck, featuring a solid surface without any openings. You can also find double-face pallets, which offer decks on both the top and bottom. This ensures even weight distribution of the products and also enhances the overall strength of the pallet racking.

Types of pallets: how to stack pallet racks efficiently

When your start stacking products, check pallets for loose boards, protruding nails, or splinters, or other damage to prevent accidents. Also, be aware of the size and weight restrictions in your region, such as those set by OSHA in the United States, ABNT in Brazil, and STPS in Mexico.

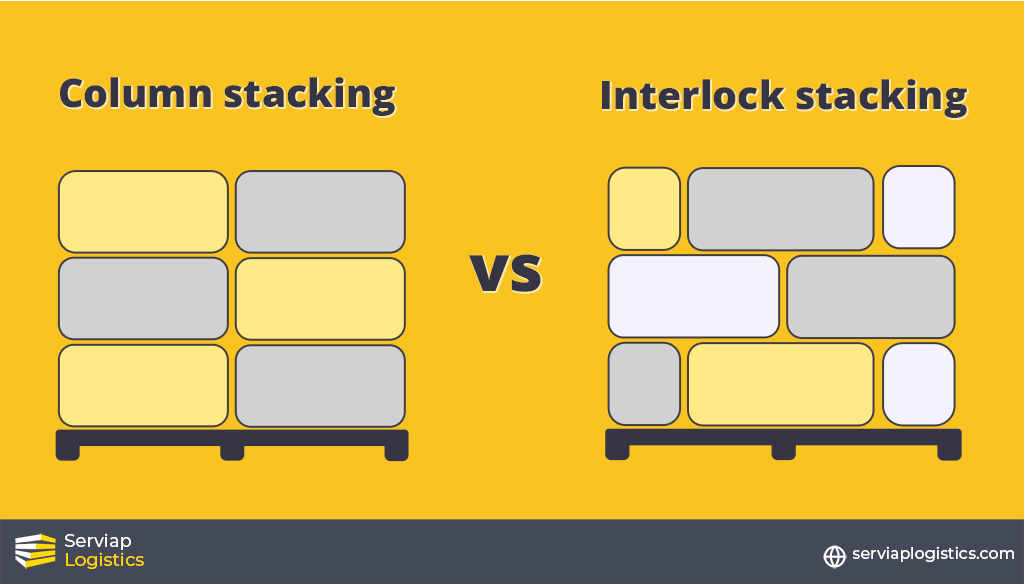

For building a system, there are two common patterns for stacking pallets according to the types of goods. Column stacking is mainly used when the boxes are the same size, have a low density, and contain soft or fragile products. Interlock stacking is the best stacking method when the boxes are of different sizes and weights.

In either pattern, heavier items should always be placed at the bottom to support and stabilize the entire stack. Knowing how to stack a pallet rack correctly means considering weights and structural integrity. Layers should be well-aligned, with proper distribution and the barcodes facing out for quick identification.

Once the items are lined up and stacked, remember to fasten or wrap the goods properly, which can be done manually or using machinery. It’s also advisable to maintain regular professional pallet inspections, to help you identify possible risks, as well as guarantee your staff is using proper lifting equipment for all types of pallets.

Serviap Logistics can help you with warehouse optimization

At Serviap Logistics, we offer a variety of services for setting up warehouses and distribution centers in Brazil, Mexico, and the United States.

Those include supplying and installing racking, labels, barriers, floor marking, and signage. Some of our clients are among the biggest and best-known companies in the world from a wide array of industries.

We are known for being able to hit tight deadlines without sacrificing quality or safety standards, and we guarantee compliance with local regulations everywhere we work.

Contact us for more information.

If you were interested in this article on different types of pallets, check out the rest of our coverage.