Table of Contents

In warehouse management, optimizing storage space is vital for efficiency and productivity, with teardrop racking a popular solution because of the versatility and flexibility it offers for storing goods.

Teardrop racking is a type of warehouse racking characterized by its unique teardrop-shaped holes on the upright frames. These holes serve as key components for locking in beams, allowing shelf heights to be adjusted quickly and easily.

This makes teardrop racking an excellent choice for warehouses with a diverse range of products. Constructed from robust materials, it can withstand the demands of a busy warehouse environment and can be implemented in different designs.

Contact us if you are seeking a supplier or installer of racking in Brazil, Mexico, or the United States.

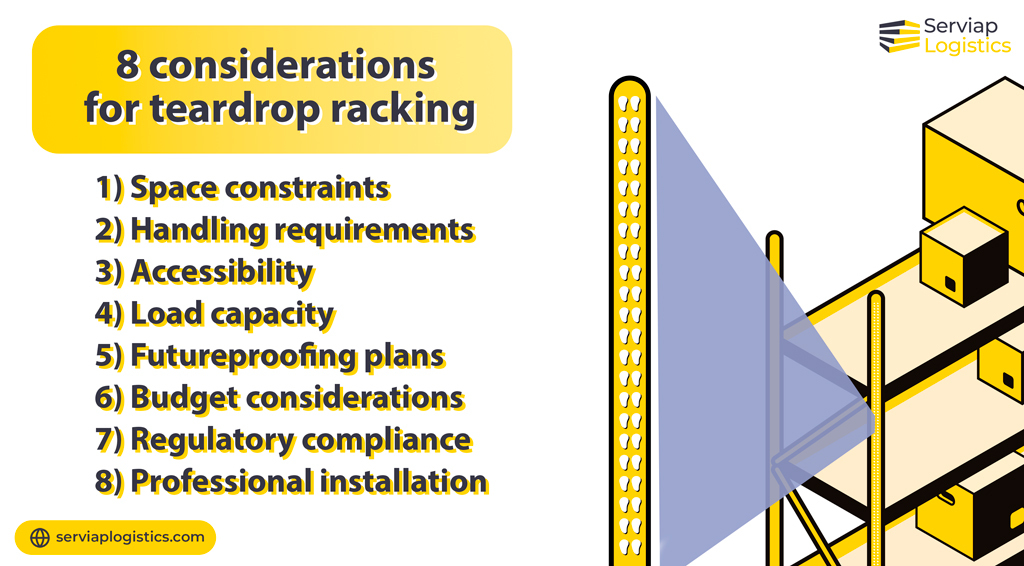

8 key considerations for teardrop racking

The integration of teardrop racking into a warehouse provides a number of benefits, as this is the backbone of any good logistics operation.

1) Space constraints

Understanding the layout and availability of space within your warehouse is essential to optimize storage. Consider the dimensions of the facility, ceiling height, and any potential obstructions that could affect the installation and utilization of teardrop pallet racking.

2) Handling requirements

Different products have varying storage requirements. Examine factors such as product size, weight, and handling frequency, as well as how mixed or uniform the types of goods are. Heavier or bulkier items may require sturdier systems. Remember that teardrop racking allows for swift adjustments.

3) Accessibility and retrieval speed

One of the key advantages of teardrop pallet racking is its accessibility, allowing for better access to each pallet. However, consider the speed at which products need to be retrieved. If you have a high turnover of goods or time-sensitive operations, it may be worth investing in additional features like conveyors or automated systems.

4) Load capacity and safety

Safety should always be a top priority. Ensure that the selected teardrop racking system is capable of supporting the weight of your products. Each rack should have a clearly labeled load capacity to prevent overloading. Additionally, implement safety features to create a secure working environment.

5) Future expansion and scalability

Plan the future expansion of your business and opt for teardrop pallet racking that can be expanded or reconfigured to accommodate changing storage needs. A warehouse setup consultant can help you establish a pallet system that is scalable in the future, which can save time and costs in the long run.

6) Budget and cost considerations

While teardrop pallet racking is known for its cost-effectiveness, it’s important to establish a budget. Factor in the initial cost of racking combined with additional features or accessories that may be required. Remember that investing in quality racking can lead to long-term cost savings through reduced maintenance.

7) Compliance with regulations

Adherence to local warehouse codes and regulations is crucial for a safe and compliant warehouse environment and avoids costly shutdowns. Ensure that the teardrop racking design meets all relevant industry standards and guidelines. This may include fire safety codes, seismic requirements, and load capacity regulations.

8) Professional installation and maintenance

Engaging a professional installation team with experience in teardrop pallet racking is essential. Proper installation ensures the stability and safety of the system. Additionally, establish a regular maintenance schedule to inspect for any signs of wear and tear, and address any issues promptly.

Exploring different pallet racking combinations

In a warehouse, choosing the right pallet rack system is essential for maximizing storage space and streamlining operations without investing in obsolete equipment. While teardrop racking is a popular choice, there are several other types of industrial storage racks that cater to specific storage needs. Most of these can be used in combination with other types.

For example, selective pallet racking allows for direct access to every pallet, making it ideal for warehouses with a wide range of SKUs (Stock Keeping Units). For storage of homogeneous products on the other hand, drive-in and drive-thru pallet racking are designed so that forklifts can enter and exit the rack structure.

Push-back pallet racking allows for high-density storage utilizing a dynamic cart system, which still provides easy access to products. Cantilever pallet racking is designed for the storage of long, oversized, or irregularly shaped items, such as lumber, pipes, or furniture.

Pallet flow racking, also known as gravity flow racking, is an excellent choice for warehouses with high inventory turnover rates, as it operates on a first-in, first-out (FIFO) basis. There is also double deep pallet racking placing, as well as other systems involving narrow aisles and mezzanine structures.

Installing teardrop racking with professional teams

Teardrop racking installation requires a series of steps that help place shelves securely. Before installation begins, it’s important to have a comprehensive plan in place. This includes a detailed layout of the warehouse space, an understanding of the types and quantities of products to be stored, and compliance with safety regulations.

Consider hiring an experienced team in teardrop racking installation. Their expertise can prevent potential long-term issues and ensure pallet racking is installed correctly. If you collaborate with experts from the beginning, they can help you in choosing the proper materials, shelves, and equipment needed.

Professional warehouse racking installers start by assembling the upright frames and attaching the horizontal beams to ensure that all components are connected. Upright frames should be anchored securely to the warehouse floor to prevent potential hazards and provide stability, while beams provide horizontal support for the pallets and ensure they are aligned with the teardrop connectors.

During installation, the trained staff can also implement safety features such as rack guards, aisle markings, and load capacity labels to ensure a secure working environment. All of this will be done in accordance with safety regulations, such as the OSHA in the United States, ABNT in Brazil, and STPS in Mexico. This way, you can improve your facility without unforeseen penalties.

Serviap Logistics supplies and installs warehouse racking

At Serviap Logistics, we supply and install a range of warehouse racking, including teardrop racking, in Brazil, Mexico, and the United States. We also offer a range of other warehouse optimization services, including signage, floor marking, and collision protection.

For anyone in need of a comprehensive package of services to support a warehouse setup, refit, or relocation, we offer warehouse project management services. We additionally supply labels and offer maintenance and industrial cleaning services.

Our ability to hit tight deadlines while maintaining the highest standards of safety and quality has seen us become the trusted partner of some of the biggest and best-known companies in the world, spanning a wide range of industries that includes agriculture, automotive, e-commerce, and wholesale.

Contact us for more information.