In warehouses and distribution centers, different shelving systems are used according to the type and flow of goods being stored. Among the most popular is teardrop pallet racking, a practical, universal style with easily replaceable parts.

A pallet rack is a storage structure, usually metal, that allows individual boxes and products to be placed on pallets. These, in turn, are positioned on beams for horizontal space utilization.

Thus, as its name suggests, teardrop pallet racking is characterized by its perforations with this shape in the columns or frames, where beams are fixed at different heights by mounting clips or screws.

As with any part of your facility, hiring warehouse racking installers is one of the best ways to ensure you get a quality teardrop pallet racking system that meets your storage and distribution needs.

In addition, working with experts installing teardrop pallet racking ensures compliance with the highest safety standards in your region, such as OSHA in the United States, STPS in Mexico, and ABNT in Brazil.

At Serviap Logistics, we distribute and install warehouse racking, among a range of other items. Contact us for more information about our warehouse solutions.

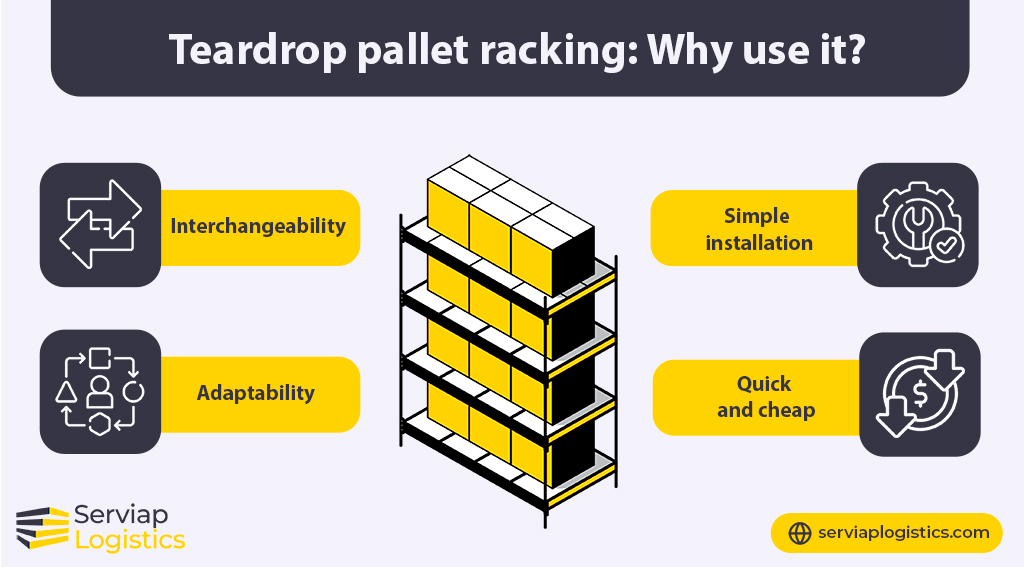

Teardrop pallet racking: benefits

Opting for teardrop pallet racking as a storage solution has several benefits for warehouses and distribution centers where they are placed. Due to its practicality and unique features, these are the advantages you should not miss:

1) Interchangeability

A teardrop pallet rack is a versatile style that allows the interchangeability of its parts, from columns to beams and other accessories that compose it.

For the same reason, this type of rack can be sold as complete kits or by parts, used or new, saving money in case one of its components needs to be replaced, so you don’t have to buy the whole structure.

2) Adaptability

Teardrop pallet racking is highly adaptable, as the beams and racks can be adjusted according to the volume of goods to be stored and fixed using mounting clips or screws.

Thanks to their great adaptability, this type of racking maximizes storage space, supports various weights and dimensions, and is an economical solution due to its interchangeable pieces.

3) Simple installation

The innovative design of the teardrop pallet racking makes it easy to place, as its parts can be assembled, interchanged, and replaced according to the needs of each establishment.

Although installing and dismantling these structures is easy, hiring a trained technician for a smooth building is best, according to the warehouse layout and in compliance with local regulations.

4) Quick and cheap

Because the design of teardrop pallet racking is so easy to place, it is relatively inexpensive and simple to maintain over a long term period.

While other types of racking may well confer advantages for specific circumstances, teardrop pallet racking has the great advantage of being low-cost. This means it can function well straight off the bat and even be used as a placeholder while you consider if more specific racking may be necessary.

Teardrop pallet racking: considerations for choosing the best

Teardrop pallet racking is part of a complex storage equipment system, so it’s worth taking the time and following some considerations to choose the best ones.

First of all, keep in mind the storage capacity of your facility. This results from multiplying the total area where the teardrop pallet racking will be placed by the maximum height allowed for stacking racks so that they do not collide with beams, lighting systems, and other building features.

The storage density is also essential since this is the ratio between the space allocated for teardrop pallet racking placement and the warehouse’s total area.

The type of goods to be stored and their characteristics will determine the number of units of the teardrop pallet racking, as well as how they will be arranged, at what height the racks will be fixed for the subsequent placement of pallets and how many of these pieces will be necessary.

Although these structures are made of metal, they have various qualities; some even have special finishes, like oil paint, to prolong their useful life and appearance. In this case, looking for a supplier that understands your project, adapts to your budget, and offers the best teardrop pallet racking type is best.

Building conditions are also critical, especially in calculating storage capacity and minimizing any risk of a collapsing structure or the impact of a forklift truck with a pallet racking system. It is also necessary to anticipate the location of doors, columns, and other structures around the storage area that may interfere with the placement of the equipment.

Finally, when designing the layout of your warehouse, take into account the flow of goods and opt for the unilateral type. This way, it will be easier to access the stored materials, whether in containers, boxes, or as individual products, deposited in the teardrop pallet racking.

Other pallet racking types to keep in mind

Pallet racking is the most conventional type of shelving. Although there are various types, they generally have teardrop-shaped perforations for attaching frames at different heights.

Selective racking, for example, adapts to any space and volume of goods, making it a practical solution for any warehouse or distribution center.

There is also drive-in pallet racking, a more complex system designed for vehicle access between aisles or interior tunnels that forms the placement of racks throughout the storage space.

A teardrop pallet racking system can also be dynamic, with FIFO (first-in, first-out) or LIFO (last-in, first-out) systems based on sloping structures that facilitate the rapid movement of goods.

You can also find mobile teardrop pallet racking placed on automated or wheeled bases that allow it to be moved and repositioned according to storage needs.

Serviap Logistics helps you to install teardrop pallet racking

At Serviap Logistics, we distribute and install teardrop racking for warehouses and distribution centers in Mexico, Brazil, and the United States.

We are also experts in signage, labeling, floor marking, and anti-collision guards. And as part of our project management service, we supervise your store’s opening, renovation, or relocation from start to finish.

Thanks to our ability to hit tight deadlines without sacrificing our commitment quality and safety, we count some of the biggest and best-known companies in the world among our satisfied clients, who hail from a wide range of industries, including automotive, construction, e-commerce, and wholesale.

Contact us if you need teardrop pallet racking or any other of our solutions for your business.