Table of Contents

Running an efficient and productive warehouse or distribution center in Mexico means guaranteeing that the facility is well set up to meet its purpose. That means properly organizing infrastructure and safety features, with the installation and placement of storage racks in Mexico being a critical concern.

Racking is used to keep goods and materials throughout the production cycle, so choosing and organizing storage racks in Mexico will be based on what they are intended to hold and for how long, with the best racking being capable of holding heavy loads and suited to use in extreme temperatures.

Anyone setting up a Mexican warehouse for the first time should consider working with a setup provider to guarantee that they make the best choices in terms of what equipment to install and where. While anyone who already has a facility should guarantee that racking inspection is carried out regularly to make sure this critical equipment remains fit for its purpose and in compliance with safety standards.

In Mexico, the Secretariat of Labor and Social Welfare regulates the handling and storage of materials through the Norma Oficial Mexicana NOM-006-STPS-2000, which establishes the operating guidelines for a warehouse, such as the obligations of the employer and employees, health and safety procedures, loading of materials and verification units.

For anyone planning to install storage racks in Mexico, some of the most commonly used are highlighted below, including information on their key characteristics.

If you are looking for support with sourcing or installing storage racks in Mexico, contact us for more information.

Storage racks in Mexico: types and characteristics

Storage racks in Mexico use a pallet as a base to support the placement of boxes and heavy materials.

The design of these structures will be according to the space distribution, the products to be stored, and the access to them. These are the most popular options in the Mexican market:

Pallet racks

Pallet racks, or conventional racks, are the most common, as they are used for general storage of goods. Pallets are adapted to the size and weight of the objects and are placed horizontally and on several levels. In addition, their stacking usually involves using stringers, mesh, and dunnage stops to provide additional security.

Double-deep

This type of storage racks in Mexico are created by positioning one row of pallet racks behind another to maximize space. The main advantage is that goods can be stored at high density. However, using forklifts is necessary to access the goods in the back rows.

Self-service racks

Known as drive-in and drive-through racking, they are used when high-density storage is necessary, as pallets can be stacked deep and high. In addition, these racks allow vehicles to drive in and drive through.

In the drive-in mode, there is only one entry or exit for the goods, so they help store goods that will remain in the warehouse for a while. On the other hand, the drive-through has a separate entrance and exit, which is ideal for the flow of high-demand products.

Dynamic racks

Thanks to their inclination, these racks take advantage of gravity to facilitate the flow of goods. Their purpose is to improve storage and streamline warehouse operations. Live racks can use FIFO (first in, first out) to accommodate pallets, support rollers, and an inclined design. They can also be LIFO (last-in, first-out), in which loading and order picking are performed at the same end of the rack.

Cantilever

This type of racking is ideal when the items are long and bulky, such as boards, pipes, sheets, rods, paper or fabric rolls, and metal profiles. To accommodate materials with these characteristics, cantilever racks have adjustable arms at various heights where the merchandise rests.

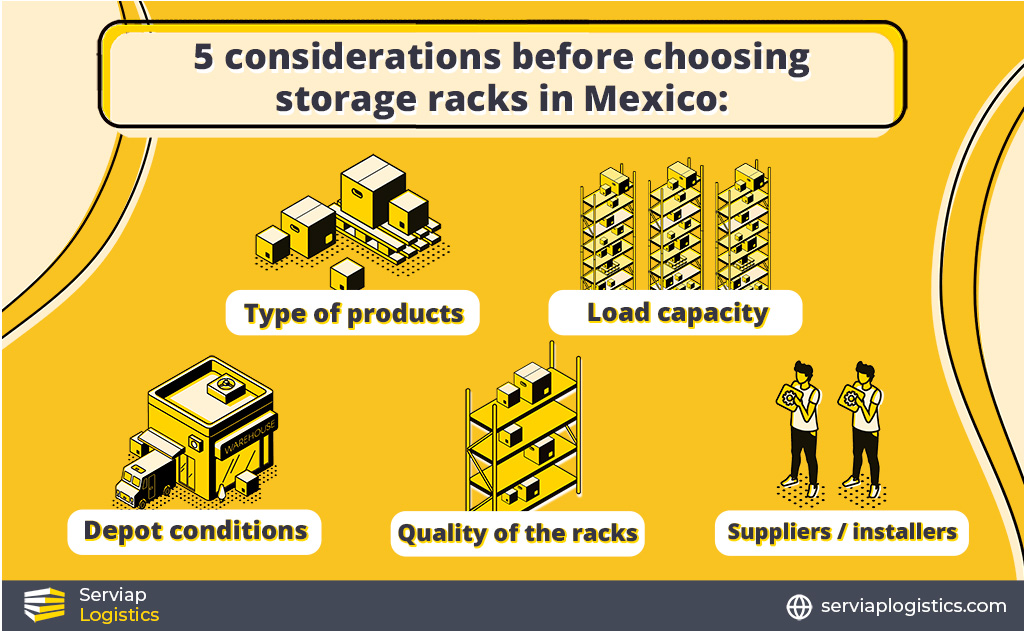

5 aspects to consider when choosing storage racks in Mexico

To choose the storage racks in Mexico that best suit your business, you should not only know the most popular types on the market and their characteristics but also take into account the following aspects:

1) Type of products to be stored

The products to be stored or distributed will determine the characteristics of the building you will have to rent, buy or even build, the type of warehouse you will manage, the necessary electrical or sanitary installations, and the storage racks that best suit your needs.

Defining the industry to which you want to offer your storage or distribution services is critical to know the specifications of your storage racks in Mexico, such as the materials and dimensions they should have. This way, you will optimize your operations and work in spaces with the least risks possible.

2) Load capacity

Knowing the load capacity of pallets and storage racks in Mexico will prevent these structures from collapsing, consequently injuring workers and damaging goods. Even if damage is avoided, structural problems cost time and money to fix.

According to NOM-006-STPS-2000, load capacity is the weight in kilograms or tons that a machine or mechanical device can lift and lower without any of its parts suffering deterioration. Make sure you know and follow these limits.

3) Depot conditions

The location, height, storage space, and construction time of the building that will house the warehouse are determining factors in choosing the best storage racks in Mexico. Different racks work better with certain layouts.

Taking into account the conditions of the building will also help you to make the necessary remodeling or adaptation of the space before starting to assemble the storage equipment. This will help you make the most of your resources before starting operations.

4) Quality

The quality of the racks will be conditioned by the budget you have for your warehouse. However, to maintain risk-free workplaces, buying storage equipment built with highly durable materials and distributed by companies with a good track record is always best.

In addition, for storage racks in Mexico to be kept in good condition, it is necessary to have them checked regularly, either by internal personnel or by an external company that offers these services.

5) Suppliers / installers

For fast, hassle-free installation, it’s best to use a group of experts who sell storage racks in Mexico and offer installation services following local regulations. Starting out with the best possible setup will make everything run smoother throughout the operational life of the facility and hiring employees in Mexico has never been easier.

These professionals can help you plan the layout of your warehouse, define critical areas and make the corresponding signage. They will also supervise the entire project, from the purchase of equipment to its correct placement.

Serviap Logistics supplies and installs storage racks in Mexico

At Serviap Logistics, we supply and install storage racks in Mexico, among other critical elements of infrastructure for warehouses and distribution centers. So whether you need warehouse racking, signage, collision protectors, or floor marking, we can help you. We also supply labels.

We also operate in Brazil and the United States, and are known for our ability to hit tight deadlines without sacrificing quality or safety standards.

That is why we count some of the biggest and best-known companies in the world among our satisfied customers, who come from industries including automotive, construction, e-commerce, and wholesale, among others.

Contact us to learn more about how we can assist you.