Table of Contents

A smart logistics warehouse is a storage or distribution business where a wide range of processes are carried out through automated systems, specialized software, and robots to increase productivity and efficiency.

Thanks to its multiple benefits, such as resource optimization and time reduction, having a smart logistics warehouse has become a priority for companies that want to stand out and offer better services compared to the competition.

To have a successful smart logistics warehouse, it is necessary to know the most popular software and the technologies that intervene throughout the production chain and help staff perform their work better.

Whether it’s a smart logistics warehouse or a cold storage warehouse, remember to comply with local regulations to provide a safe workplace for your employees, maintain your facilities in optimal condition and preserve the building.

For example, in the United States, you must follow what is indicated by OSHA; in Brazil, by ABNT; while in Mexico, it is stipulated by STPS, such as the NOM 006 STPS, regarding material handling and storage.

Contact us to learn how we can help you with your smart logistics warehouse in the USA, Brazil or Mexico.

Benefits of a smart logistics warehouse

Thanks to the implementation of software, technologies, and specialized robots, a smart logistics warehouse represents many advantages for the owners of this type of business.

1) Automation and process optimization

Automation consists of using technological tools to minimize the intervention of operators within a warehouse. As a result, the organization and management of stored products, the main processes within these businesses, are optimized, and possible human errors are reduced.

2) Better use of resources / time reduction

By automating specific processes, the time required to receive and arrange merchandise, as well as its preparation and dispatch from the warehouse, is reduced. Shorter operating times mean savings in resources.

3) Improved control and accuracy

When trained technologies are implemented to perform specific activities, such as mechanical arms to move products from one rack to another or scanners for reading warehouse labeling systems, control, and accuracy in warehouse management are improved.

4) Reduced operational risks

In a smart logistics warehouse, by minimizing human intervention in specific tasks, accidents are minimized, such as collisions or spillage of toxic products that can endanger the lives of employees and the quality of the goods.

5) Higher storage capacity

Space optimization is also a feature of a smart logistics warehouse since the technologies used help better organize the warehouse layout design.

6) Increases productivity

The automation of processes, time savings, and greater control and precision will help improve the overall productivity of the warehouse, which also means higher profits for the owners.

Cons of a smart logistics warehouse

A smart logistics warehouse has many upsides. However, before thinking about setting one up, you should consider the cons of this type of storage and distribution business:

1) High initial investment

To set up a smart logistics warehouse, it is necessary to invest in machinery and technology such as robots, computers, software, sensors, and other devices, which are not usually cheap.

2) Staff training

Besides all the technological devices and programs you will have to buy and install, you will need to train your staff, since a computer will now assist in the mechanical tasks your employees used to do.

3) Costly maintenance

The maintenance of your intelligent logistics warehouse will be higher since, in addition to supervising that your mechanical equipment is working correctly, you must ensure that the technology you use is up to date.

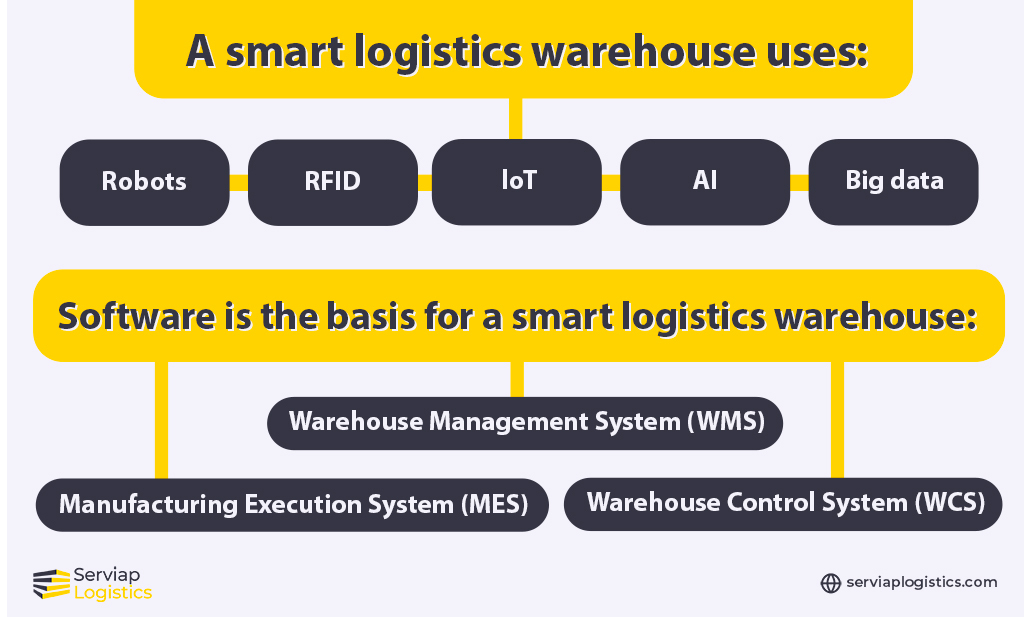

Tools found in a smart logistics warehouse

A smart logistics warehouse will need to use plenty of high-tech equipment. This ranges from large mechanical and/or electronic devices to more conceptual tools that provide a framework for operation through communication and connection. They employ one or more of the following systems.

Robots

Robotics in warehouses help increase productivity and efficiency, which is why they have gained popularity recently. Among the most widely used devices are automated guided vehicles (AVG), which help transport goods with the help of cables, electrical belts, and other systems.

Also popular are automated storage and retrieval systems known as AS/RS for handling goods; and collaborative robots, which assist in routine and mechanical tasks in the warehouse, such as order picking.

On the other hand, robotic arms are articulated devices with greater freedom of movement that help lift and arrange goods, in addition to participating in the assembly of products and other tasks within production warehouses.

Radio Frequency Identification (RFID)

This data storage and retrieval system is based on intelligent tags for automatic identification (Auto ID) of products or materials.

RFID tags are attached to the goods to be stored and, unlike traditional bar codes, have small antennae that allow them to receive and respond to radio frequency signals emitted by RFID devices.

Thanks to this type of system, it is possible to know from an office in a smart logistics warehouse the stock without needing to read the tags placed on each of the stored goods.

IoT for logistics industries

The internet of things (IoT) in the logistics industry has various applications, but according to Forbes, one of the most popular is tracking and monitoring shipments, thanks to different wireless devices with sensors that follow the location of shipments.

It also helps in inventory management, mainly thanks to the use of smart labels, such as RFID tags, that help to know where the products are and the warehouse’s current capacity.

Likewise, implementing IoT in a smart logistics warehouse helps retrieve relevant data and information that aids in future warehouse operations, like predicting equipment failures and when they need maintenance.

Artificial Intelligence

From personnel selection through AI recruiting tools to workplace accident prevention (it monitors working conditions and alerts on any risky situation), artificial intelligence is revolutionizing the logistics industry.

In general, AI implementation is crucial to improve efficiency and reduce costs in any warehouse. Still, it also helps with warehouse space management, as it can help suggest how to organize inventory and take advantage of each space.

AI can also be implemented in inventory control thanks to its ability to process large amounts of data, generate reports on stored merchandise and avoid potential bottlenecks in the supply chain.

Big data

To improve operations within the intelligent logistics warehouse, it is necessary to use big data and its volume, variety, velocity, veracity, and value collected information automatically and massively.

In logistics companies, big data also helps to better control stock, adjust transport routes and distribution flows (such as optimizing the last mile) and provide better customer service by detecting problems in time that may interfere with the supply chain.

Big data feeds AI, so it is worth having access to a diversity of both internal and external data for processing to improve all operations within the smart logistics warehouse.

Software used in a smart logistics warehouse

For smooth operation, your smart logistics warehouse will require the adoption of specialized software, such as those described below:

1) Warehouse Management System (WMS)

This software streamlines the management of the smart logistics warehouse from when goods enter the building, are labeled, taken to the storage area, and then picked and prepared for distribution.

A WMS integrates with tools such as barcode and QR code scanners and other management systems. Hence, it helps increase process efficiency, improve time, and save resources.

Before implementing any WMS, consider the types that exist in the market: standalone, which uses warehouse hardware; cloud-based that can be public or private; and integrated, an option that is part of more complete solutions such as supply chain management (SCM).

2) Manufacturing Execution System (MES)

A smart logistics warehouse that also performs part of the production of the goods it stores will require the implementation of an MES. This system tracks and documents the transformation of raw materials into products ready to be marketed.

An MES works in real-time, providing vital information for decision-making during production regarding the management of inputs, personnel, and machinery.

By executing and monitoring production, an MES helps to reduce bottlenecks, track ongoing activities, assign tasks, and better control quality.

3) Warehouse Control System (WCS)

This software integrates with the WMS to interface and control all automated equipment within the warehouse, such as conveyors, product sorters, and automated storage and retrieval (AS/RS) systems.

The WCS directs real-time activities and maintains the optimal operation of the warehouse. Some of its primary functions are information exchange, statistical data collection, and report generation.

A WCS is also responsible for assigning tasks to warehouse subsystems and giving operators directions. In this way, workloads are balanced for both machines and personnel.

Serviap Logistics can help establish a smart logistics warehouse

At Serviap Logistics, we are experts in storage businesses and distribution centers in Mexico, Brazil, and the United States so that we can advise you with the establishment of your smart logistics warehouse.

In any of these territories, we take care of signage, labeling, placement of collision protectors, floor marking with tape or epoxy paint, and equipment assembly. We also offer project management services to oversee your warehouse’s opening, renovation, and relocation from start to finish.

The quality of our service and attention to detail have made us a leader in logistics, which is why we are adding more satisfied customers every day from sectors such as automotive, construction, e-commerce, and wholesale, among others.

Contact us to find out how we can help you with your smart logistics warehouse.