Table of Contents

If you are about to setting up a warehouse distribution center where you store goods and also deliver them, consult this complete guide to find out what equipment and attachments are essential and the steps to follow to start operations without any problem.

While you can handle your warehouse layout design and research what you need for your own, it is best to consult an expert. These professionals not only take care of the installation of the storage equipment but also distribute the areas of your business based on the best flow of goods and space optimization.

Additionally, working with a certified technician ensures that you minimize any risks and comply with local regulations regarding safe workplaces, which in the United States are monitored by OSHA, in Mexico by STPS, and in Brazil by ABNT.

At Serviap Logistics, we help you to setting up a warehouse distribution center in the United States, Mexico, and Brazil, where we offer quality services under the highest safety standards.

Contact us for more information about intelligent storage solutions for warehouses and distribution centers.

For setting up a warehouse distribution center, you will need:

Starting a storage business can be surprisingly easy, especially when you rely on an expert who often offers consulting services and is also a professional distributor and installer of industrial accessories along with understanding the nuances of setting up a warehouse distribution center.

In addition to the equipment, you should consider the placement of other elements, such as warehouse labeling, signs, and floor marking, so that your business operates in the best possible manner. This way, you ensure the safety of your employees, the goods are kept in optimal conditions, and the facilities are protected. So, when setting up a warehouse distribution center, don’t forget that you’ll need:

Project management services

If your storage and distribution business is new, you want to renovate it, change your shelving, move equipment within the facility or dismantle it to another location, you will need the professional services of a project manager when setting up a warehouse distribution center.

Project management specialists make any assignment easier by scheduling the sequence of activities, reporting on their progress, defining deliverables, and meeting the requirements for the proper installation and operation of a warehousing business from start to finish.

Signage

Signage is one of the key elements when setting up a warehouse distribution center, as it helps keep workplaces safe, provides protection for operators and goods, and increases productivity.

There are many types of warehouse signage, such as aisle signage, which optimizes work environments and limits heavy loads. Safety signage, meanwhile, has a specific system of symbols and colors. There are informational hanging signs, logo signage, door dock signs, and identification codes too.

Whatever signage is used when setting up your warehouse distribution center, the material, size, and position must be appropriate for operators and anyone visiting the facility to read and understand it without problems.

Labeling

Rack, floor, and shelf labels also help keep the warehouse or distribution center well organized, as placing them correctly helps to quickly identify the location of products in the countless positions that can exist in a storage facility.

Rack labels are a worldwide standard for traceability in logistics units. On the other hand, floor labels must be functional and resistant, easy to attach and remove, and slip-resistant. At the same time, shelf labels minimize the time between production and distribution and improve accuracy in operations.

When creating these visual guides, it is best to approach a professional who, in addition to helping you with the design, will create a color and shape code and a product and lot classification, either by barcodes or alphanumeric combinations. This way, you can maximize efficiency during the flow of goods through your warehouse.

Floor marking

Floor marking, either with epoxy paint or adhesive tape, is also essential when setting up a warehouse distribution center, since its purpose, among other functions, is to delimit transit areas, workspaces, and storage of goods.

If you are looking for a quick and easy solution to mark the floors of your store, the best option is to use adhesive tape, but if you have more time and a major investment, epoxy paint is your alternative.

Equipment Assembly

Equipment assembly, such as machinery, workstations, shelving, racks, and any other structure for storing materials, is fundamental when setting up a warehouse distribution center.

When you hire technicians to install equipment, you not only guarantee that they adhere to the layout design of your warehouse, considering columns, doors, and any element of the structure, but also that they follow safety standards and meet your budget and deadlines.

Installation of collision protectors

Finally, you should also consider installing anti-collision guards to minimize any risk of collapsing racks or collision of cargo vehicles, which can endanger workers, goods, and the building structure.

So, to safeguard the safety of personnel and not disrupt your operations, consider that, when setting up a warehouse distribution center, you will need to hire an expert who distributes and installs posts, bollards, handrails, column and wall guards, and any other anti-collision protectors.

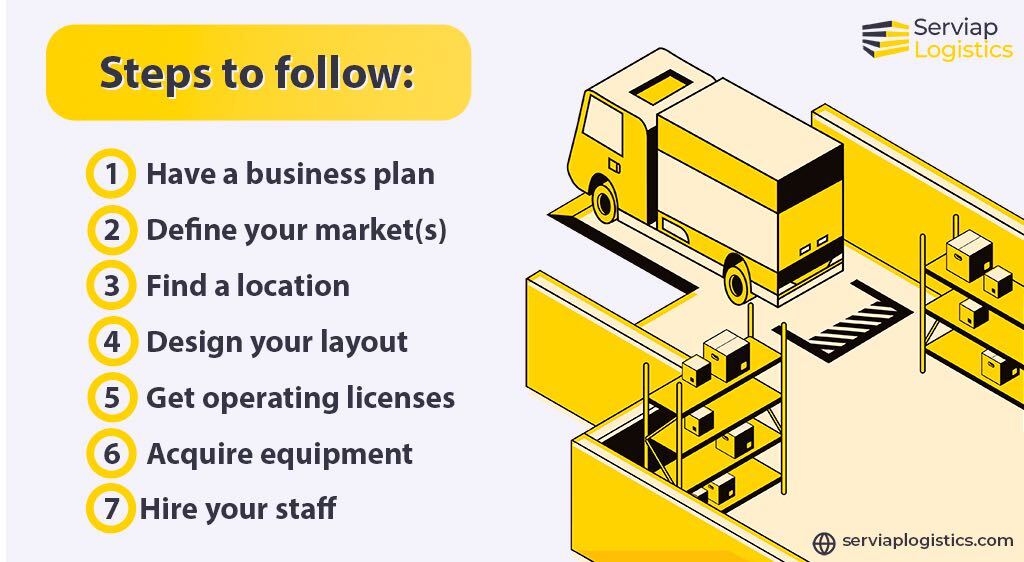

7 steps to setting up a warehouse distribution center

Now that you know what the general considerations are, such as the necessary equipment and signaling systems, follow these seven steps to launch your warehouse distribution center smoothly:

1) Have a business plan

Planning is essential to succeed in any business, and a warehousing and distribution business is no exception. So, when setting up a warehouse distribution center, think about your objectives, mission, and vision. You also need to define your company’s name and other elements that have to do with your business identity.

Also, be precise about your budget, where you will offer your services, the resources needed to set up a warehousing business, and even who your competitors are, what services they provide, and at what price.

2) Define your market(s)

Defining the market and the industry to which you will offer your services is crucial to know what type of warehouse you will set up, where, and if your building needs special structures or any adaptation.

Suppose you will be storing and distributing perishable products, such as food. In that case, you will need to install a warehouse with refrigerated systems and special shelving, for example. Therefore, defining your market will help you know if you should offer training to your employees for handling delicate or dangerous goods or special machinery.

3) Find a location

Whether you choose an industrial city to setting up a warehouse distribution center, a settlement near a customs port, or a busy metropolis, you need to take into account the products you will store and distribute, so you will know which location and type of property is best for you.

It all depends on your budget, but renting a building to operate as soon as possible is best since it will likely already have the electrical, sanitary, and fire control facilities you need. However, you can also make the adjustments that you consider pertinent or build a facility from scratch, which may take you more time and resources but will be just as you need it.

4) Design your layout

Designing the critical areas of your warehouse is necessary before starting operations, so your workers will know where the loading and unloading area, goods receiving, storage space, picking and shipping, and other vital spaces such as offices, restrooms, cafeteria, and maintenance room are located.

An efficient warehouse layout considers aspects such as the flow of goods, vehicle circulation, loading capacity and density, storage equipment and dimensions, and the safety standards of the territory where you offer your services and sustainability.

5) Get operating licenses

Wherever you plan to setting up a warehouse distribution center, it is necessary to comply with local regulations, ensuring that any work center is a safe space for employees and obtaining other commercial and merchandise handling licenses.

Generally, to obtain these permits, specific documentation must be submitted, such as authorization for the use of the company name, a commercial act, bank accounts, registration as a taxpayer, roll with the social security entity for workers, and anything else required by the local government

6) Acquire equipment

A successful and profitable warehouse or distribution center is equipped with specialized, quality machinery and structures. These elements facilitate operations and are crucial to maintaining a steady flow of goods.

To acquire and install the necessary equipment that matches your storage needs, it is best to seek the advice of experts who, in addition to being distributors, are expert placers and, if necessary, offer training in properly using machinery, tools, and storage equipment.

7) Hire your staff

Wherever you decide to run a warehouse distribution center, besides the equipment, safety features, and visual marking system, you will need to hire trained, responsible personnel to help you operate your business smoothly.

A warehouse staff generally consists of shipping and receiving personnel, machine operators, material handlers, forklift drivers, janitorial staff, managers, and maintenance people.

While you can hire your workers directly, an alternative is to outsource your staff recruitment to an expert, such as an employer of record (EOR) or professional employer organization (PEO), to find talent and manage your human resources.

Serviap Logistics helps you in setting up a warehouse distribution center

At Serviap Logistics, we are experts in setting up a warehouse distribution center in territories such as Brazil, Mexico, and the United States, where we work according to the highest quality standards.

We also take care of signage, warehouse labels, floor marking, equipment assembly, and placement of collision protectors. In addition, if you want to renovate your warehouse, move equipment, or change location, we will manage your project from start to finish.

Thanks to the quality of our service, attention to detail, and adherence to strict deadlines, we have clients and partners in various sectors, such as automotive, e-commerce, wholesale, and more.

Contact us to learn about all our solutions for setting up a warehouse distribution center.