Table of Contents

Industrial storage racks are essential to operate any warehouse or distribution center. Choosing the best types for your setup will help you optimize your business and provide better service during the entire goods supply chain.

Industrial storage racks are structures, mostly metal, designed to maximize space and accommodate different types of goods and materials, making them a key element in any storage or distribution business operation.

SEE ALSO: Industrial warehouse cleaning services: 3 critical elements

Choosing the proper industrial storage racks will depend on several factors, such as the products circulating through your facility, the building conditions, the nature of your business, and the budget you have to set up your warehousing company.

While there are many types of industrial storage racks, we list what you should consider when choosing the ones that best suit your needs and the most common types you can find on the market.

Your choice should be according to expert advice and comply with your region’s workplace safety regulations. If you live in the United States, check what OSHA says about storage racks; in Mexico, the government agency is the STPS, while in Brazil, the the ABNT is in charge of dictating these rules.

At Serviap Logistics, we are distributors and experienced installers of industrial storage racks in Mexico, Brazil, and the United States. Contact us for more information.

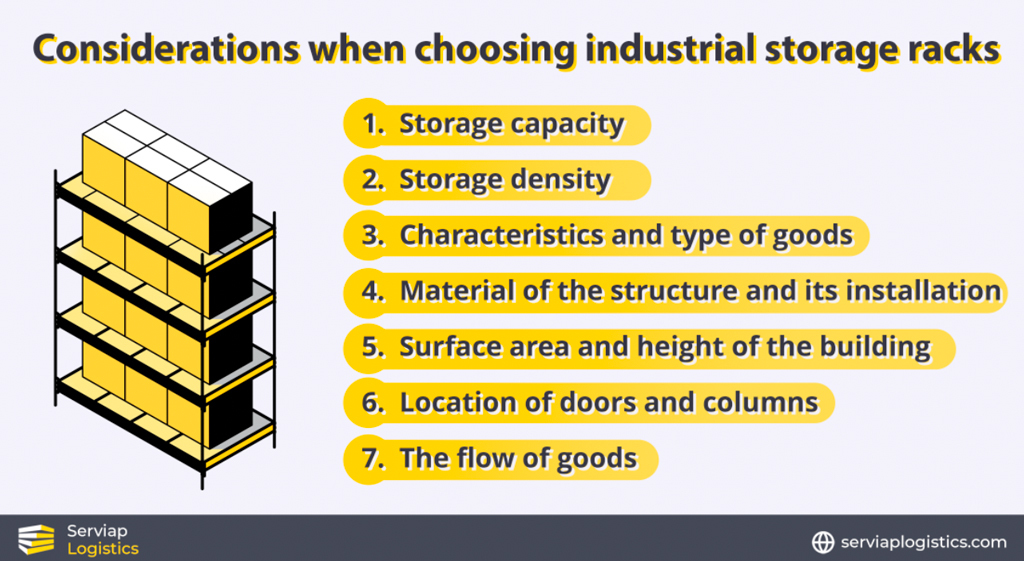

Industrial storage racks: important considerations

When choosing or designing an industrial storage racks system, remember the following points:

- Storage capacity: To determine the facility’s storage capacity, it is necessary to know the total surface area of the space to place the industrial storage racks and multiply it by the maximum height allowed for stacking shelves.

- Storage density: is the ratio between the available storage area and the total warehouse area.

- Characteristics and type of goods: The selection of industrial storage racks will be based on the weight, dimensions, and kind of merchandise to be stored. For example, looking for frames for cold or freezing environments will be necessary if perishable goods are involved.

- Material of the structure and its installation: Industrial storage racks are made of metal and have wire shelves for pallet placement, which are highly resistant materials. However, in addition to considering the different qualities, you should look for someone to install this storage equipment. Relying on a professional to purchase equipment assembly products and services is always best.

- Surface area and height of the building: To choose the industrial storage racks that best suit your business, you need to be aware of the floor conditions and if there are bumps, cracks, or any other imperfection that may affect the rack’s stability. By knowing in advance the maximum height of the facility, you can avoid beams, ceilings, light fixtures, pipes, and more when placing the storage equipment.

- Location of doors and columns: Identifying where the entries are in the building is vital when choosing and placing storage racks because you don’t want them to hit your shelves, damage them or obstruct the passage when you open the doors. As for columns, figuring out where they are will help you accurately calculate the number of racks you need and whether you should place collision guards nearby so you don’t damage the building’s structure.

- The flow of goods: when designing the warehouse layout, the flow of goods is a fundamental principle for making the best use of space and operating efficiently. Thus, considering the flow of goods, which is usually one-sided, you will know how to locate your industrial storage racks.

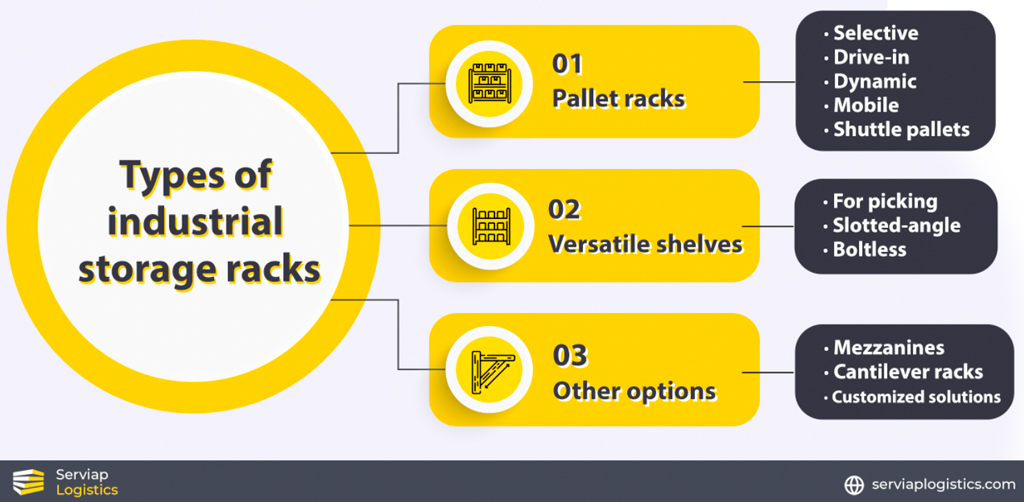

Types of industrial storage racks

1) Pallet racks

Pallet racks are those that, as their name suggests, have pallets to house the goods entering and leaving the warehouses and distribution centers. The pallets can be arranged at different heights, depending on the volume of goods to be stored.

Selective racks can be a universal storage solution, adaptable to any space, weight, and size of goods. You can place pallets with goods in these industrial storage racks and handle them by forklift.

A drive-in rack is a storage system designed for vehicular access. The layout of the racks forms large interior loading lanes or tunnels through which the forklift passes, with support rails for the pallets.

Dynamic racks have an inclined design supported by rollers for rapid movement of goods which literally move through the racking system. They can use a FIFO (first in, first out) or LIFO (last in, first out) system.

There are also mobile industrial storage racks. These are placed on automated bases that allow them to be moved. This way, individual aisles can be opened or closed according to storage needs.

Racks with shuttle pallets are a semi-automatic storage system that has as a central element an electric cart that loads and unloads pallets in the aisles inside the racks, increasing precision and reducing operation times.

2) Versatile shelves

Picking shelves are designed for storing and manually collecting merchandise, so they usually accommodate small and lightweight goods, including individual products. This system is often combined with conventional palletizing.

Slotted-angle shelves are economical, versatile storage systems that are easy to disassemble and modify according to the needs of the warehouse or distribution center. They are perfect for light loads and low-bulk products.

This classification also includes boltless shelves designed for small, even fragile, products. Being a flexible storage system with a stable metal structure, they allow the shelves to be adjusted to different heights.

3) Other industrial storage racks

Mezzanines are removable storage systems used in very tall industrial buildings since they allow doubling or tripling their height to store large-volume goods.

Cantilever racks are designed to hold pipes, rods, fabric rolls, and long goods. They are characterized by a simple structure with columns and cantilever arms on which the products rest. These arms can move at different heights.

While these are the most popular industrial storage racks, you can also design customized solutions that combine one or more systems to facilitate the flow of goods and optimize operations within the building. It all depends on the needs of your warehousing business and finding a distributor or installer who understands your project.

Serviap Logistics distributes and installs industrial storage racks

At Serviap Logistics, we are distributors and expert installers of industrial storage racks for your warehouses or distribution centers in Mexico, Brazil, and the United States.

In all three countries, we also offer signage, labeling, collision protection, and floor marking with tape or epoxy paint. And if you’re about to open, renovate or relocate a warehouse, we offer project management services to oversee the plan from from start to finish.

The quality of our service and attention to detail speak for themselves, which is why we’re adding more satisfied customers every day from industries such as automotive, construction, e-commerce, wholesale, and more.

Contact us if you need industrial storage racks, to learn more about our solutions for your warehouse or distribution center.