Table of Contents

Making sure that all people using them know how to stack a pallet rack can be crucial to guaranteeing efficiency, productivity, and safety in a warehouse or distribution center.

Pallet racks are in many ways the backbone of warehousing facilities, taking up a significant amount of floor spaces and being used to store goods, materials, and other items until they are used or sent onwards.

Racking comes in many forms, with some essentially being heavy-duty shelving systems while others can be complex pieces of equipment with electrical elements. Properly training workers on how to stack a pallet rack will partly be down to the types of racking you have installed.

SEE ALSO: 6 warehouse racking options to improve efficiency

But keeping workers safe will not just be down to training them on how to stack a pallet rack. Because the condition of those racks is also an important consideration, with periodic warehouse racking inspection needed.

Guaranteeing that all staff members are using the appropriate safety gear and holding the relevant certifications to undertake their roles will also be critical.

If you need pallet racking, supplied, installed or inspected in Brazil, Mexico, ord the United States, contact us today.

How to stack a pallet rack — 6 important tips

Although this procedure may differ from warehouse to warehouse according to the type of goods and merchandise stored, as well as the type of racking being used, below some general tips on how to stack a pallet rack are shared that should be of use in most instances .

1) Inspect your pallet

Before asking yourself how to stack a pallet rack, confirm the pallets are in optimal condition and do not have cracks, are broken, or have any structural damage.

The pallets are the base of the structure where the goods and materials will be stacked, so checking them before placing any box on them is necessary. Remember that it is vital that your storage structures are in excellent condition through regular inspections.

2) Plan your stacking pattern

Planning is essential to optimize resources and make warehouse operations more efficient. To know how to stack a pallet rack, for example, you must know in advance which products you will store and which pallets you will use.

It will depend on the type of goods and materials to choose the appropriate pallets, but the most common patterns for stacking boxes are:

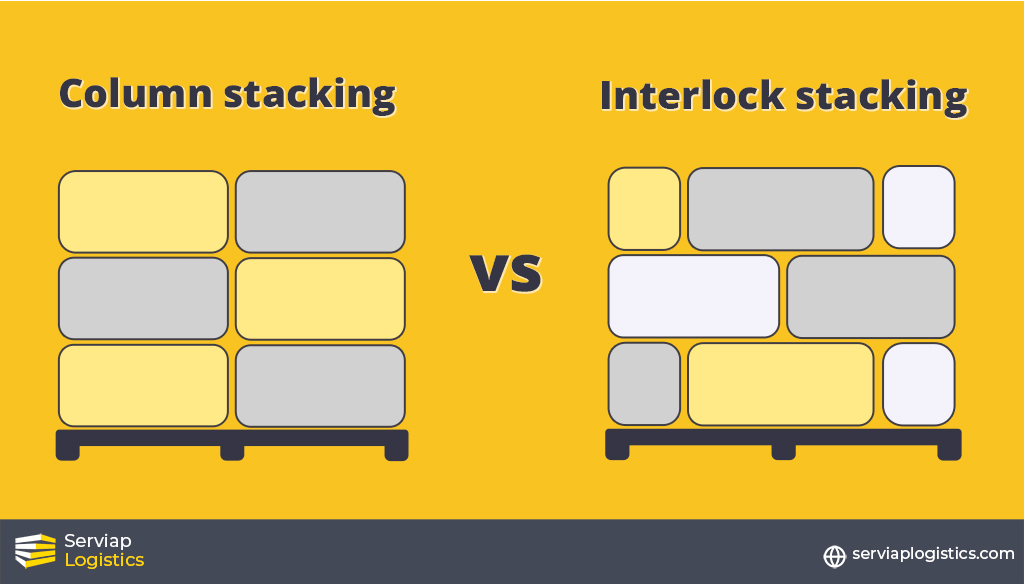

- Column stacking. This is the most common stacking pattern. It is mainly used when the boxes are the same size, have a low density, and contain soft or fragile products. Unfortunately, columns can fall down if they are not stacked properly, so this solution is only sometimes recommended.

- Interlock stacking. This is the best stacking method when the boxes are of different sizes and weights or are all the same size but very dense. Although this solution is not the most practical due to the rotation method used to place the boxes and the irregular weight distribution, it gives excellent stability to the entire load.

3) Distribute the weight

No matter what stacking pattern you choose, as a general rule, heavier items should always be placed at the bottom to support and stabilize the entire stack. Knowing how to stack a pallet rack correctly means considering weights and structural integrity.

This practice will not only prevent lighter packages from being crushed and damaged but also create a lower center of gravity, resulting in a more robust structure that can carry heavier weights without fear of collapse.

4) Align the boxes

When you start building your stack of products, make sure the first layer is as close as possible to the edges of the pallet but not sticking out and overhanging the aisles. Then, each layer should line up with the first layer, and so on.

A well-aligned first layer, with the bar codes facing out for quick identification, will facilitate this entire process of how to stack a pallet rack and prevent possible damage during the shipping and handling of goods. It’s crucial for efficiency in operation.

5) Fasten the goods

Once the items are lined up and stacked according to their dimensions and the stacking pattern you chose, tie them together with straps. This will keep the boxes attached to the pallet and reduce the probability of falling.

The straps must be made of highly resistant materials such as polypropylene, polyester, or steel. You will need at least two, one to secure the load vertically and one horizontally. Protectors between the boxes and the straps will also be required to prevent item damage.

6) Wrap goods properly

Now that the boxes are stacked and aligned to the edges of the pallet, with the barcodes visible and securely fastened, you can give the entire load more stability by covering it with stretch wrap.

This is the final step in how to stack a pallet rack. This process can be done manually or with a shrink-wrap machine. Also, an alternative is prefabricated pallet covers which, although less affordable and more space-intensive, can be reused.

Additional tips on how to stack a pallet rack

Do not use damged pallets or racks. It may seem obvious, but it is worth repeating: employee safety comes first in any warehouse. So check pallets before stacking any products on them, especially for loose boards, protruding nails, or splinters, to avoid damaging boxes or causing them to fall over.

Be aware of the size and weight restrictions. To figure out how to stack a pallet rack, the height and weight limits must be addressed. The stacked boxes should never exceed 15 feet in height or 400 square feet in area, but this will be determined by the type of products to be stored and distributed, as well as the dimensions of the warehouse.

The maximum weight of the load will be determined by the type of pallet used, as well as its condition. The standard size of a pallet is 48 inches x 40 inches (123 centimeters x 102 centimeters), with each board 3 ½ inches wide and five-sixteenths of an inch thick (0.8 centimeters), and it can carry up to 4,600 pounds (2,086 kilos). If you opt for plastic pallets, higher load capacities are possible.

Use proper lifting equipment. To prevent warehouse employees from lifting heavy loads and injuring themselves, use lifting equipment to perform this work quickly and safely. The most common are forklifts, with a bifurcated platform raised or lowered while loading pallets. There are also pallet jacks, electric and manual, with wheeled carts and a lever or handle to lift and move the pallets for loading materials.

Serviap Logistics provides, installs, and inspects racking

At Serviap Logistics, we provide, install and inspect warehouse racking in Brazil, Mexico, and the United States. We also provide and install a range of other features, including warehouse signage, floor marking and collision protection.

Additionally, we offer comprehensive project management services to oversee a warehouse setup, refit, or relocation from start to finish.

We count some of the world’s biggest companies among our satisfied clients and partners, covering a wide range of sectors, including automotive, e-commerce, and wholesale, among others.

We are known among our clients for being dedicated to upholding the highest safety standards wherever we work, including being OSHA certified in the United States.

Contact us today to find out more about how we can assist you with a warehouse setup checklist.

If you were interested in this article about how to stack a pallet rack, check out the rest of our coverage.