Saber cómo montar un almacén puede ser la diferencia entre el éxito y el fracaso de tu negocio. Un almacén o centro de distribución bien planificado será más eficiente y seguro, pues facilitará el trabajo fluido con interrupciones mínimas.

Tanto si se parte de cero como si se reorganiza un espacio ya existente, la planificación y ejecución cuidadosas son cruciales, razón por la cual muchas empresas optan por trabajar con un consultor de instalación de almacenes.

Un consultor tendrá un historial de ayudar a las empresas a identificar las ubicaciones ideales y maximizar el uso del espacio, garantizando al mismo tiempo el cumplimiento de las normativas locales, como las establecidas por la OSHA en Estados Unidos, la ABNT en Brasil y la STPS en México.

Si estás pensando en cómo montar un almacén, las principales preocupaciones son la ubicación, la forma, los productos, el presupuesto y la integración tecnológica, entre otras.

Serviap Logistics ofrece servicios de instalación de almacenes en Brasil, México y Estados Unidos. Contáctanos para más información.

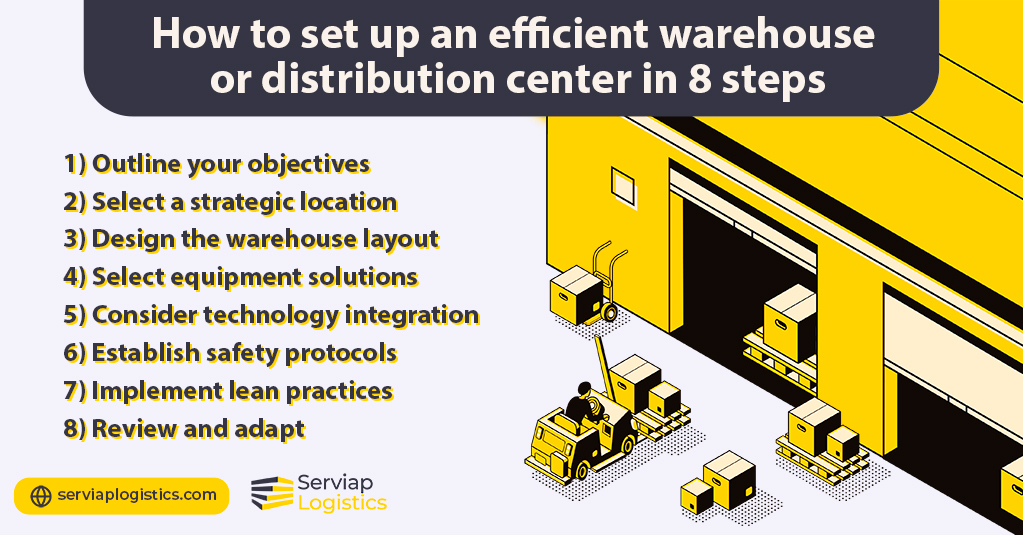

Cómo montar un almacén: 8 pasos clave

Cuando se trata de entender cómo montar un almacén, aunque ningún proyecto será igual a otro, hay una serie de pasos clave que tú o tu proveedor de instalación de almacenes tendrán que seguir.

1) Esboza tus objetivos

Al momento de decidir cómo montar un almacén, hay que tener en cuenta para qué se quiere. ¿Es la velocidad la clave o la seguridad lo primero? Puede que tengas que sacrificar un área para ganar ventaja en otra, o puede que simplemente quieras ahorrar tiempo y dinero en extras innecesarios.

La forma en que debes planificar la instalación de tu almacén depende del tipo de mercancías que gestiones, así como de tu modelo de negocio. Elegir ideas de diseño de almacenes basadas en una forma de I, por ejemplo, es estupendo para una instalación de gran flujo, pero no será adecuado para una empresa que espera almacenar mercancías durante largos periodos de tiempo.

2) Selecciona una ubicación estratégica

La ubicación es uno de los aspectos más críticos al esclarecer cómo montar un almacén. Los factores a tener en cuenta son la proximidad a los centros de transporte, la accesibilidad de los vehículos de reparto y expedición y la disponibilidad de mano de obra capacitada.

También puede haber desgravaciones fiscales u otros incentivos disponibles para invertir en determinadas zonas de territorios concretos, por lo que merece la pena averiguar si hay alguno de ellos cerca de donde se está buscando montar un almacén.

3) Diseña la distribución del almacén

El diseño de la distribución del almacén también requiere una planificación estratégica. El recorrido de las mercancías y los materiales debe contemplarse desde el momento de la llegada hasta la expedición. Hay que dividir y zonificar el espacio para que los procesos que se realicen in situ no se crucen entre sí.

Para diseñar una distribución eficiente, puedes tener en cuenta las distintas zonas de tus instalaciones. Empieza por las secciones de carga y descarga, que necesitan un acceso fácil. A continuación, destina una parte importante del espacio al almacenamiento, así como a la recogida y el envío. Por último, no olvides las zonas de recepción y oficinas.

4) Selecciona las soluciones de equipamiento

Para ayudarte a hacer frente a los numerosos elementos de una operación logística, invierte en soluciones de equipamiento para almacenes que puedan mejorar la gestión de las instalaciones. Al planificar cómo montar un almacén, es clave contar con un buen sistema de estanterías para palés, que permita un almacenamiento vertical adecuado y ahorre espacio.

Además de seleccionar los tipos de estanterías adecuados, necesitarás una señalización completa que pueda funcionar junto con los sistemas de etiquetado y códigos de barras y la cinta o pintura de señalización del suelo. Para la seguridad operativa, serán necesarias barreras anticolisión y otros elementos de protección.

5) Considera la integración de la tecnología

La tecnología puede ayudar a configurar un almacén manteniendo procesos más fluidos a largo plazo. Las plataformas de software optimizan la eficacia de la recepción, la preparación de pedidos, el embalaje y el envío, mientras que los sistemas de gestión de almacenes pueden reunirlo todo en un único lugar para obtener una visión general de los procesos fácil de consultar.

Un sistema de códigos de barras en el almacén ayuda a controlar el volumen y la ubicación del inventario, lo que permite a los trabajadores realizar su trabajo de la manera más eficaz posible. Conectadas a sistemas automatizados de clasificación y envasado, estas tecnologías pueden ahorrar tiempo y reducir los costes de mano de obra.

6) Establece protocolos de seguridad

La seguridad en los almacenes es fundamental tanto para los empleados como para los empresarios. Tendrás que establecer un programa de formación en seguridad y proporcionar equipos de protección individual (EPI) a todo el personal. Realiza inspecciones de seguridad periódicas y etiqueta las zonas y materiales peligrosos. Además, crea un plan de respuesta de emergencia.

Los protocolos de seguridad no sólo son importantes para proteger al personal, los productos y la infraestructura, sino que también te ayudarán a ahorrar dinero al evitar multas de instituciones reguladoras o cierres costosos.

7) Implementa prácticas de mejora

Cuando pienses en cómo montar un almacén, ten en cuenta los principios de Lean, que se centran en eliminar los residuos y optimizar los procesos. Nuevas técnicas como las 5S (clasificar, ordenar, abrillantar, normalizar, mantener) permiten conservar un espacio de trabajo organizado y libre de desorden. Esto significa menos distracciones y retrasos.

Las prácticas regulares de limpieza interna son necesarias para levantar la moral del personal, proteger los bienes y mantener la organización. Los servicios de limpieza de naves industriales te ayudarán a mantener todo limpio, ordenado y en perfecto funcionamiento.

8) Revisa y adapta

Las necesidades de tu empresa y las condiciones del mercado evolucionarán con el tiempo. Revisa periódicamente las operaciones de tu almacén y realiza los ajustes necesarios. Esto puede implicar reconfigurar la distribución, actualizar la tecnología o evaluar los procesos para seguir siendo competitivos.

Después de determinar cómo configurar un almacén según los requisitos iniciales, debes planificar los cambios. Esto puede significar prepararse para el futuro invirtiendo en la tecnología adecuada, o en un espacio que pueda ampliarse si tu empresa crece.

Cómo montar un almacén: las ventajas de un asesor

Puede resultar complicado decidir cómo montar un almacén o un centro de distribución, por lo que es aconsejable trabajar en estrecha colaboración con un consultor de instalaciones. Un profesional puede prestar servicios de gestión de proyectos, desde la planificación inicial hasta la renovación de los establecimientos, así como asesoramiento para inspecciones.

La instalación de equipos y las operaciones dentro de un establecimiento deben ser seguras. Un consultor de instalación de almacenes se asegura de que las medidas de seguridad se ajustan a la normativa de cada territorio y se basan en las mercancías y los materiales que se van a almacenar y distribuir.

Te ayudarán a crear un sistema holístico y contribuirán a una configuración eficaz. Contratar a un consultor permite a los directivos concentrarse en su negocio y disfrutar de la tranquilidad de saber que la instalación de su almacén se ha hecho correctamente y no dará problemas en el futuro.

Serviap Logistics ofrece servicios de preparación de almacenes

En Serviap Logistics tenemos amplios conocimientos sobre cómo montar un almacén o centro de distribución en Brasil, México y Estados Unidos.

Estos servicios incluyen el suministro y la instalación de señalización de almacenes, marcaje de suelos, protectores anticolisión y estanterías, al tiempo que ofrecemos limpieza industrial y etiquetas.

Nuestro compromiso con los más altos niveles de seguridad y servicio ha hecho que algunas de las empresas más grandes y conocidas del mundo se hayan convertido en clientes satisfechos nuestros, abarcando sectores como la agricultura, la automoción, el comercio electrónico y la venta al por mayor, entre otros.

Contáctanos para obtener más información sobre cómo montar un almacén.