The Occupational Safety and Health Administration (OSHA) is part of the U.S. Department of Labor and is responsible for ensuring that all workers operate in a safe and healthy environment. The agency oversees a number of regulations and training programs, with different types of OSHA certification available to both companies and individuals.

This agency was established in 1970 to create a stronger system of accountability for the safety of people among the companies that employ them. OSHA certification is relevant to a wide range of workplace types, with the ultimate intent of preventing injuries and fatalities.

According to OSHA, about 3.5 million people suffer workplace accidents in the United States each year, many of which could have been prevented.

In warehouses and distribution centers, OSHA regulations cover a wide range of aspects, related to aspects such as the design of the warehouse layout, as well as specific elements of the facility, such as the colors and dimensions of the warehouse floor signage.

At Serviap Logistics, we offer warehouse installation, refurbishment and relocation services in Brazil, Mexico and the United States. Contact us today for more information.

What is OSHA certification?

OSHA certification takes two main forms: that obtained by individuals so that they can be considered for certain types of job functions, and that acquired by workplaces to ensure that the environment is as safe as possible for the people who work there.

This article focuses on the latter, and more specifically on warehouses and distribution centers.

OSHA certification for a warehouse or distribution center demonstrates that a facility meets a wide range of guidelines and has systems and processes in place to make the space as safe as possible for the people who use it.

Operating with poor design, lacking clear signage in the warehouse or not working in accordance with internal standards and official legislation can seriously compromise the safety of workers and lead to legal problems.

In addition, while OSHA certification is required by law and crucial for worker protection, it also contributes to the smooth operation of a warehouse or distribution center.

Although OSHA is a U.S.-centric organization, the standards and guidelines it sets are often considered best practices internationally, and many countries have similar regulations. Even where OSHA certification is not a legal requirement, the safety stipulations it entails are often advisable.

However, it is in the United States that OSHA is empowered to conduct unannounced inspections of workplaces, with significant penalties for non-compliance. OSHA certification is therefore an absolute necessity in the United States.

OSHA certification in warehouses

In the United States, the fatal injury rate in the warehouse industry is higher than in many other industries, and there are many areas within warehouses that are potentially hazardous and pose an ongoing risk to workers.

Accordingly, OSHA pays special attention to warehouses to ensure that they are configured in the best possible way to reduce the risk of accidents and minimize potential hazards to workers.

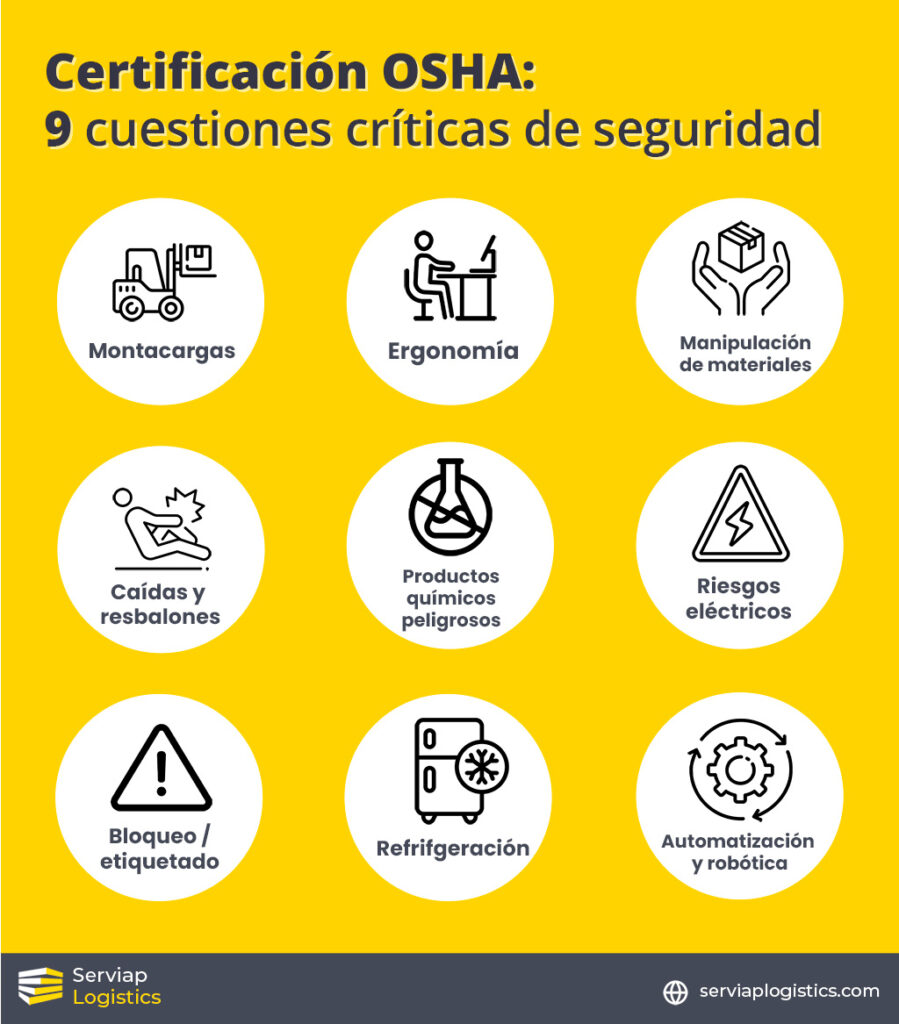

Among the many operational elements of a warehouse, OSHA certification provides guidance on the following nine areas:

1) Forklifts

Operating a forklift is not a task that should be assigned to just anyone. These are powerful and potentially dangerous machines. OSHA certification requires that only trained individuals may work as operators, to prevent injury to others or damage to equipment, inventory and the warehouse itself.

Stipulations include:

Certified forklift operators must be 18 years of age or older and wear a seat belt when operating.

Distances and speed must be respected.

Under no circumstances should personnel be lifted.

2) Ergonomics and musculoskeletal disorders.

Warehouse workers are always at risk of injury in the workplace due to frequent loading of heavy items, so OSHA certification suggests certain options so they can perform their job without injury to the body.

Stipulations include:

- Seats must have lumbar support

- Boxes to be transported must have a maximum weight of 35 pounds (15.8 kilograms).

- A system of task rotation and work cycles should be developed to avoid repetitive strain injuries.

3) Material handling

Warehouses are spaces where there is often the potential for personal injury and facility damage due to poor storage or handling. One of the biggest risks is falling items, so goods must be properly secured on shelves.

Stipulations include:

- Installation of protections on the racks to prevent damage due to contact with forklifts.

- Ensure that all materials are stacked carefully and do not exceed load capacities

- Racking arrangement so that the heaviest loads are at the bottom.

4) Falls and slips

Falls are a frequent cause of worker injury. Workers should be aware of best operating practices to prevent injuries or fatal consequences from falls, slips or trips in hazardous work areas, especially in elevated positions.

Stipulations include:

- Workers must be provided with a protective helmet.

- Workers using items such as ladders or platforms must be trained.

- Floors and walkways should be kept clean and free of objects that could cause falls.

5) Hazardous chemicals

If there are chemicals in the warehouse to which employees are at risk of exposure, the following OSHA certification standards must be followed:

- All personnel must be informed of the dangers of chemical use.

- A list of chemicals and safety data sheets should be kept.

- Container labels should be kept visible.

In addition, there may be other specific legal regulations for certain chemicals in certain territories.

6) Electrical hazards

Warehouses often have many electrical elements, so employers must ensure that they are in proper working order and free from hazards such as short circuits or sparks. Specialized fire control systems that do not conduct electricity are also necessary.

Stipulations include:

- Equipment must have clear labeling and instructions.

- Overloading of individual sockets should be avoided.

- Power supply systems must be grounded.

7) Blocking / labeling

When workers perform maintenance or servicing of equipment, they can be electrocuted and seriously injured. Employers should establish a clear and easy-to-follow lockout system in case accidents occur.

Stipulations include:

- Persons using potentially hazardous machinery must be isolated from the operator.

- Workers must be properly trained to operate and maneuver machinery.

- Workers must be familiar with the lockout system and receive continuous training.

8) Cold storage

When working in a cold storage facility, workers may be at risk of cold stress, hypothermia and musculoskeletal disorders. Doors and other entry points must be secured and controlled to avoid the risk of workers becoming trapped.

Stipulations include:

- Workers should be trained on the hazards of working in coolers and keep doors open to allow egress.

- Workers must have the opportunity to adapt to working in this environment.

- Insulating and protective clothing should be provided and replaced if it gets wet.

9) Automation and robotics

As the use of new technologies to perform automated tasks and improve productivity becomes more widespread, new dangers are coming to light. Their use is not without regulations, and this is an area that is particularly open to change in the future.

The stipulations include:

- Conveyor belts and automatic wrappers must be correctly installed.

- Workers must be aware of the dangers of industrial robots.

- All this equipment must undergo periodic reviews and evaluations.

Serviap Logistics offers warehouse picking services

Serviap Logistics supplies and installs warehouse elements in Brazil, Mexico and the United States.

These include shelving, labels, signage, floor marking and collision protection. We also offer project management services and can oversee the installation, remodeling or relocation of a warehouse from start to finish.

We count some of the world’s largest companies among our satisfied customers and partners, covering a wide range of industries such as automotive, e-commerce, wholesale and others.

As a family business that has grown internationally after starting in Mexico, we are committed to service excellence and pride ourselves in offering personalized service to every customer.

We are also dedicated to maintaining the highest safety standards wherever we work, including OSHA certification in the United States.

Contact us at to learn more about how we can help you with OSHA certification.

If you were interested in this article on OSHA certification, check out the rest of our coverage.