Table of Contents

Warehouse floor markings are crucial for maintaining safety, best practices, and high efficiency in the daily operations of a warehouse or distribution center.

Because warehouse floor markings indicate where both people and machinery can or cannot operate, as well as their direction of travel. In many countries, colors and dimensions used for warehouse floor markings are closely regulated.

For the United States, the Occupational Safety and Health Administration (OSHA) oversees warehouse floor markings, among many other aspects of workplaces, so it is ideal to work with a supplier that has OSHA certification. In the case of Mexico and Brazil, similar regulatory agencies are involved.

There are two main types of warehouse floor marking to choose between: taped or painted. The former is made with strong and durable adhesive tape, while painted marking uses epoxy paint. Either of the two has great advantages. In order to make the best decision, it is wise to consult with experts in warehouse project management.

If you are located in Brazil, Mexico or the United States and need someone to install warehouse floor markings, contact us today.

Warehouse floor markings: key considerations

Warehouse floor markings most commonly use lines or stripes to separate areas within the warehouse. It is a critical part of maintaining safety in warehouse layout design.

These easily visible and clear stripes allow everyone using the facility to be aware of how the space should be organized and used, as well as helping with warehouse security measures. Common functions of warehouse floor marking inside a facility include:

- To delimit and mark different work areas.

- To provide a clear direction for pedestrian traffic.

- To reinforce safety signs.

- To mark restricted or prohibited areas.

The first decision to make is in choosing material for your warehouse floor markings. The most common options are tape or paint. They differ in durability and cost but in both cases adjustments and redesigns are possible later.

There are several factors to consider when choosing the most appropriate option, including the type of flooring and the likelihood of the markings being changed. Variables such as durability, strength, and cost will all factor into the decision, and warehouse floor marking that is best for certain types of warehouse may not be appropriate in another.

The most common type of warehouse floor markings is an adhesive tape designed to be placed on the floor. These are usually made of highly resistant materials, such as vinyl. One big pro is that can be applied and immediately used. But it is also flexible, so it can be removed and reapplied with relative ease. Finally, it is cheaper to apply.

Going with epoxy paint for warehouse floor markings gives you the most durable results. There are some significant differences, however, compared to marking with adhesive tapes. This option is attractive and can withstand both wear-and-tear and chemical cleaning. On the other hand, epoxy paint is more expensive to apply.

Warehouse floor marking size and colors

Although color will vary depending on the function of the marking, the sizing should be consistent. OSHA recommendations are that stripes should be between two and six inches in width, with four inches being the standard for warehouse floor markings.

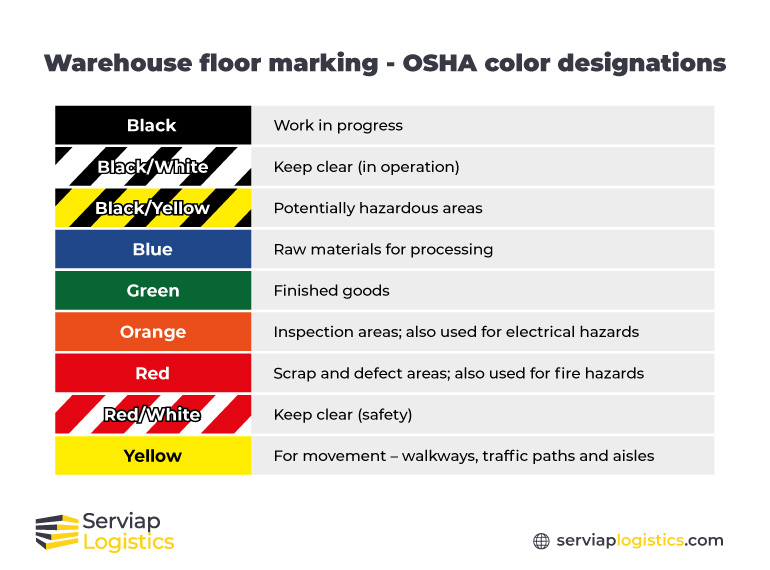

Warehouse floor markings help keep people safe. The color of a stripe or box indicates what happens or what may be present in the area. Color codes can be flexible, although hazards must be marked in red or yellow.

For extra emphasis, hazardous areas are often marked with alternating colors. All employees should be familiar with the color code, and guides should be available and clearly signed. The following colors are standard across most workplaces:

- Black: Work in progress

- Black/White: Keep clear (in operation)

- Black/Yellow: Potentially hazardous areas

- Blue: Raw materials for processing

- Green: Finished goods

- Orange: Inspection areas; also used for electrical hazards

- Red: Scrap and defect areas; also used for fire hazards

- Red/White: Keep clear (safety)

- Yellow: For movement – walkways, traffic paths and aisles

Country-specific regulations for warehouse floor markings

Brazil

In Brazil, the agency responsible for regulation is the Secretariat of Labor Inspection which reports to the Ministry of Labor and Employment and is in charge of enforcing legal regulations. The regulatory norms (Normas Regulamentadoras or NR), correspond to the obligations and duties that employers are obliged to comply with to ensure the safety and health of workers in the workplace. These regulatory standards are based on Law No. 6,514.

Mexico

In Mexico, the Secretaría del Trabajo y Previsión Social (STPS) is the agency in charge of developing the country’s safety regulations. Regarding regulations in the workplace, it is the Mexican Official Standard NOM-003-SEGOB-2011, signs and notices for civil protection, which establishes the series of rules to be followed in the use of colors, shapes and symbols in the workplace in order to prevent risks to workers.

United States

In the United States, the agency responsible for warehouse floor markings regulations is the Occupational Safety and Health Administration (OSHA), which is part of the U.S. Department of Labor.

OSHA is responsible for ensuring that all workers operate in a safe and healthy environment. OSHA regulations cover a wide range of issues, related to specific elements of the facility, such as colors and dimensions of warehouse floor markings.

Serviap Logistics can help with your warehouse setup

At Serviap Logistics, we provide and install warehouse features in Brazil, Mexico, and the United States.

Those include warehouse racking, labels, warehouse signage, floor marking and warehouse collision protection. We also offer project management services, and can oversee your warehouse setup, refit, or relocation from start to finish.

We count some of the world’s biggest companies among our satisfied clients and partners, covering a wide range of sectors, including automotive, e-commerce, and wholesale, among others.

As a family-owned company that has grown internationally after starting out in Mexico, we are committed to service excellence and pride ourselves in providing a personalized service to every client.

We are also dedicated to upholding the highest safety standards wherever we work, including being OSHA certified in the United States.

Contact us today to find out more about how we can assist you with a warehouse setup checklist.

If you were interested in this article about warehouse floor marking, check out the rest of our coverage.