Table of Contents

In warehouses and distribution centers with heavy goods or high volumes of traffic, dynamic warehouse floor demarcation helps improve efficiency and security.

Because warehouse floor demarcation allows you to designate zones for particular uses, keep pathways and aisles clear, control traffic, and ensure the safety of personnel.

For anyone intending to demarcate the floor of a distribution center or warehouse in Brazil, the first decision to make is which material to use, as warehouse floor demarcation can be applied in several ways, each of which comes with its advantages and drawbacks.

It is worth noting that if you are seeking a provider of warehouse floor demarcation, they will sometimes refer to the service by other names, including warehouse floor marking and warehouse floor line painting.

Contact us if you are looking for a provider of warehouse floor demarcation services in Brazil, Mexico, or the United States.

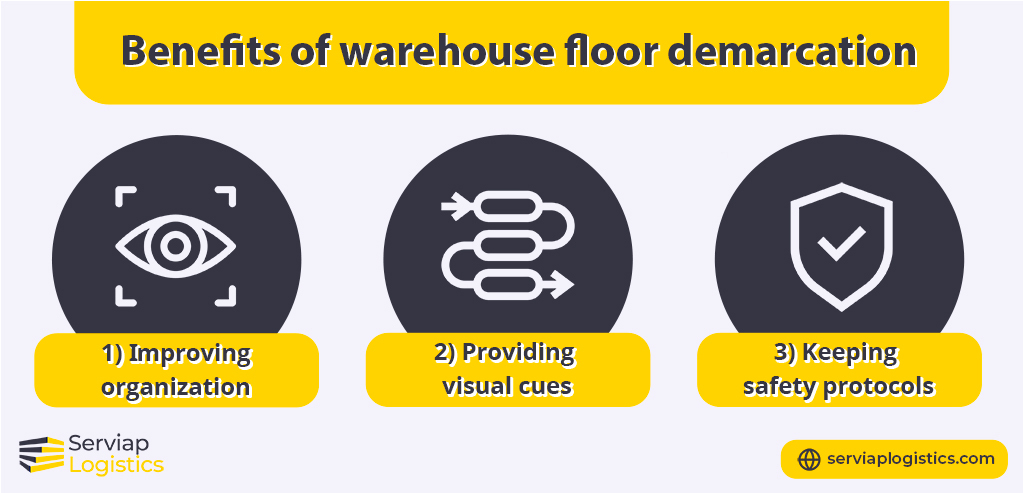

Warehouse floor demarcation: 3 key benefits

Warehouse floor demarcation unlocks key advantages for a logistics operation. From enhancing protection to optimizing storage capacity and productivity, demarcation is a crucial element in any warehouse management strategy.

1) Improving organization

Warehouse floor demarcation provides a literal roadmap for organizing products, machinery and infrastructure. By outlining zones for different types of products or operations, it becomes easier to locate and access items quickly. This translates into streamlined workflows, reducing the time spent searching for or rearranging inventory. Ultimately, this leads to higher productivity.

2) Providing visual cues

Floor marking serves as a visual device within a warehouse. Bold lines indicate designated pathways, loading areas, and hazard zones. This visual guidance is particularly important in large or busy warehouses, where multiple processes are taking place at the same time. Employees can quickly and accurately navigate the space with minimal risk of collisions or accidents.

3) Keeping safety protocols

Clear warehouse floor demarcation contributes to creating a safer work environment, identifying areas, emergency exits, and potentially dangerous equipment. Demarcation helps enforce compliance with safety regulations, ensuring that employees and visitors alike are aware of and adhere to established safety protocols. This can help you reduce workplace incidents.

Common types of floor marking in Brazil

Choosing the right materials ensures longevity and more accurate visibility. In Brazil, long-lasting epoxy or thermoplastic paint are frequently used for floor markings. These materials offer excellent durability, being able to withstand heavy traffic and wear.

Some factors to consider when choosing the most appropriate option for warehouse floor demarcation include the type of flooring, duration, and flexibility. Epoxy paint is very resistant to chemical cleaning or heavy transit in high-traffic areas. However, paint is relatively expensive, and the floor needs to undergo proper treatment before the paint is applied.

Alternatively, there are many types of warehouse floor marking tape to choose from. This is adhesive tape applied to the floor, which allows for practical removal and reapplication. They usually are more cost-effective compared to other methods, and faster to apply. However, if application is not well handled, it can lose integrity, especially in areas with heavy foot traffic.

You can also embed warehouse demarcation markings directly into the floor. This choice is usually found in operations that won’t need much adaptation, as it is a long-lasting decision.

Finally, there are also sign projectors to demarcate areas via light which is cast on floors, walls and machines. This approach avoids the need for physical markers.

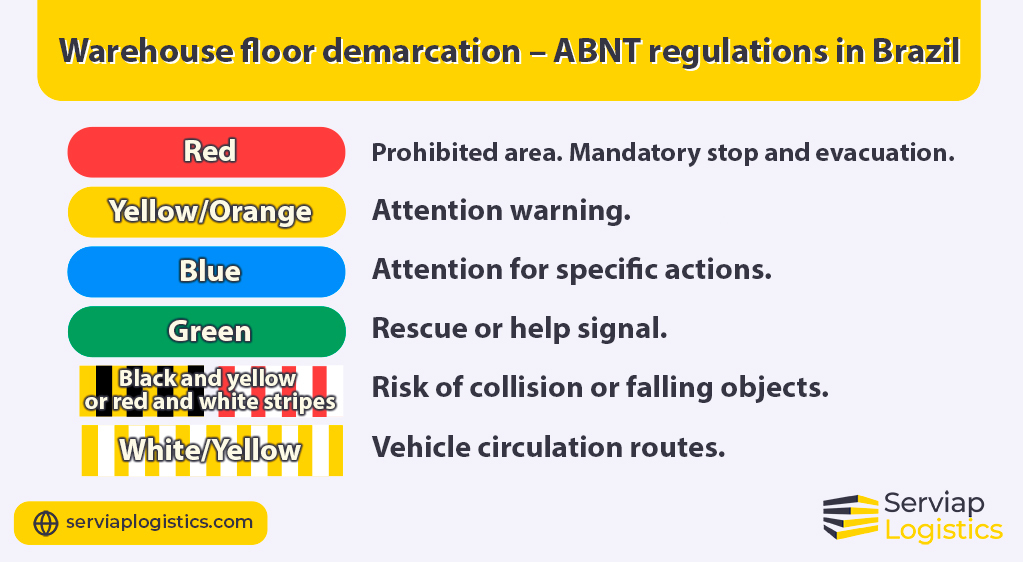

Color regulations for warehouse floor demarcation in Brazil

In Brazil, warehouse floor demarcation and signage measures are dictated by the NBR 15.524-2/2008 and NBR 7195:2018 standards of the Brazilian Association of Technical Standards (ABNT). Whatever material you choose to use, one of the most important features described in such norms concerns the colors and patterns of floor markings:

Red: Prohibited area, potentially dangerous area, and firefighting equipment. Mandatory stop and evacuation.

Yellow/Orange: Attention warning.

Blue: Attention for specific actions or behaviors, such as the obligation of wearing personal protective equipment in a certain areas.

Green: Rescue or help signal. Should be applied on doors, exit routes, first aid kits, or any space that is a safe destination.

Black and yellow or red and white stripes: Areas with a risk of collision with obstacles and falling objects.

White/Yellow: Vehicle circulation routes.

For extra guidance, managers can also consult other ABNT norms. The NR-11 sets guidelines for overall material handling and storage, while the NR-12 addresses machinery and equipment safety.

Furthermore, the NR-26 can provide extra guidance for safety signs and colors, as it regulates safety markings for general businesses and institutions, which can eventually to applied for warehouses as well.

Ensuring training and inspection in Brazilian warehouses

Beyond the ABNT color norms, Brazilian warehouse operations are subject to various regulations outlined by agencies such as the Brazilian Institute of Occupational Safety and Health (Fundacentro) and the Ministry of Labor and Employment (MTE). These regulations establish guidelines for safety and operational standards, including demarcation requirements.

Warehouse safety standards also indicate that ongoing personnel training is necessary for workers to better understand warehouse floor demarcation codes. This requirement ensures traffic and operations are as smooth and secure as possible, avoiding missteps. Training personnel involves communicating to them all kinds of safety protocols, from the meaning of colors to other visual cues.

After training, it’s important to ensure regular inspection of warehouse floor demarcation to lessen the potential for deterioration of materials. The correct habit of keeping inspections helps enhance operational safety, identify possible deficiencies, comply with legal standards, and even keep staff more aware. In the long run, this can reduce expenses by avoiding costly incidents and hazards.

You can execute periodic inspections within your own staff. However, you should also collaborate with a professional warehouse setup consultant or inspector who can provide expert insight and preventive measures, depending on the business’s location and nature. Professional teams assist in fulfilling the necessary standards to make your establishment a safe and risk-free environment.

Serviap Logistics can assist you with floor marking services

At Serviap Logistics, we help with the installation, remodeling, and management of warehouses in Brazil, Mexico, and the United States. Everywehere we work, we do so according to the highest quality standards, including ABNT and MTE in Brazil.

Our services include warehouse floor demarcation, whether you need taping or epoxy paint. We also offer warehouse setup consulting and inspection to help you in ensuring the longevity of materials and operations. Additionally, we supply and install warehouse signage, collision protection and warehouse racking, among others.

Contact us to find out more about how we can assist you.