Table of Contents

Today, leading logistics businesses are those that, in addition to opting for automation and digitization of their processes, are concerned about improving energy efficiency in warehouses to reduce their environmental footprint and be in tune with the global green initiative.

By making better use of the resources needed to operate these businesses, such as electrical power and the hydrocarbons that run machinery, energy efficiency in warehouses has environmental benefits and helps reduce costs and stay competitive.

Many processes are performed in warehousing businesses, so energy consumption is high, especially in smart logistics warehouses that implement advanced technologies. According to the U.S. Energy Information Administration (EIA), energy consumption in the industrial sector of the USA is expected to increase between 5% and 32% by 2050.

Thus, thinking about energy efficiency in warehouses is more necessary than ever, especially since these logistics businesses use lighting, heating, air conditioning, and refrigeration systems, one of the special features of cold storage warehouses.

At Serviap Logistics, we are experts in warehouses and distribution centers in Mexico, Brazil, and the United States, where we operate following the highest standards, like OSHA regulations. Contact us to find out how we can help you.

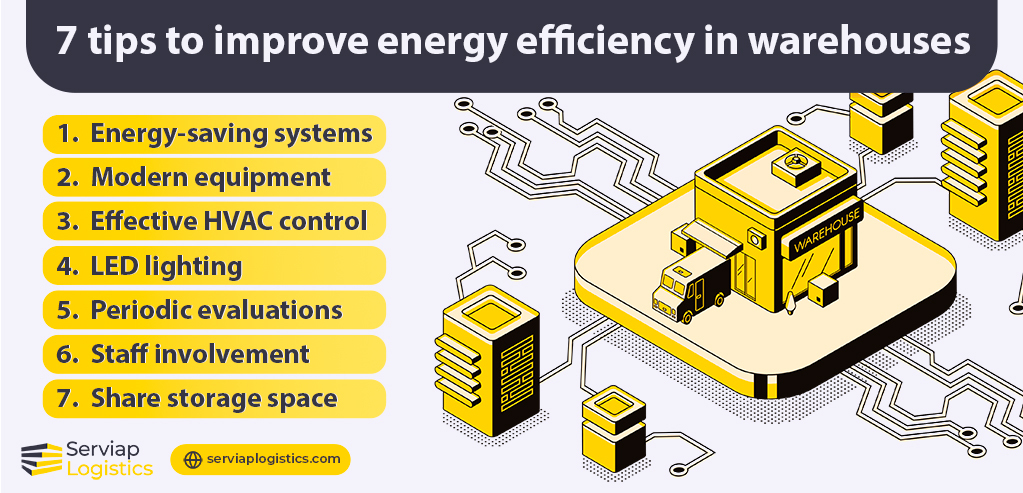

7 tips to improve energy efficiency in warehouses

1) Implement energy-saving systems

Maintaining the energy efficiency of warehouses and distribution centers can be simple and inexpensive. You can start with implementing low-investment energy-saving systems, which are simple actions with excellent results.

For example, if you want to improve the energy efficiency of warehouses, have an optimal warehouse layout design where the flow of goods is one-sided. It also helps to turn on machinery only when necessary, set times to activate or turn off artificial lighting, or place insulation in certain areas to minimize heat or cold transfers to other spaces.

For your energy-saving systems to be successful, have checklists to help you verify if the staff is following your action plan, if the storage equipment is working as expected, or even if the electrical installation you have is heavy-duty, well placed and provides you with the voltage you need.

2) Purchase of modern equipment

From machinery for processing raw materials to forklifts for loading and unloading goods, much of the logistics equipment for operating a warehouse runs on hydrocarbons, highly polluting organic compounds.

However, thanks to the modernization of the industry, it is now easy to find on the market electric or battery-powered logistics equipment with solar panels that help maintain the energy efficiency of warehouses at the same time as underlining green credentials.

Changing your traditional equipment to a modern one that uses green energy may represent a significant initial investment. However, you will save on energy consumption in the long run, and these machines can have a longer useful life, so you will also spend less on replacing them.

3) Get an effective HVAC control

In logistics businesses, especially where delicate or dangerous goods are stored, heating, ventilation, and air conditioning systems must be installed to keep these products in optimal conditions, which consume large amounts of electricity.

Avoiding these systems is not an option to maintain the energy efficiency of warehouses, but you can manage their usage as expected, such as closing doors and windows when turning them on, placing insulation, or opting for equipment with low energy consumption.

Regular maintenance of your HVAC system, such as changing filters, air vents, and ventilators, is vital to ensure that it works properly to avoid wasting energy and, consequently, paying expensive bills.

4) Choose LED lighting

LED lighting has been one of the most practical solutions for logistics business owners looking to stay ahead of the curve and improve the energy efficiency of warehouses and distribution centers.

This type of lighting consumes up to 80% less energy than traditional halogen lighting systems. In addition to these savings, the bulbs emit little heat, last longer, and are easy to install.

LED lighting also helps increase facility safety by producing a strong, bright light. The bulbs withstand shocks and vibrations without breaking and have resistance thanks to their protection against dust or water, so they have a longer service life.

5) Perform periodic evaluations

Periodic evaluations within the warehouse are essential because they help you identify the conditions of your storage equipment, such as racks in poor condition and how the property is in general.

While you can form a team within your business responsible for conducting periodic reviews, it is best to hire an expert to help you improve energy efficiency in warehouses.

These professionals will check your electrical installations to detect any energy leaks and even if there are any short circuits. Consequently, their expert knowledge will help keep your business safe and avoid accidents.

6) Keep your staff involved

To improve the energy efficiency in warehouses and distribution centers, it is necessary that the owners and managers of these types of businesses are informed and constantly involve all staff.

Whether through training or fact sheets, staff should be made aware of environmental best practices and any processes within the facility that contribute to improving the energy efficiency of warehouses.

To get staff involved, warehouse managers must foster a sense of ownership among their workers, make them feel part of the organization, and that their actions, no matter how small, add up to improving warehouse energy efficiency.

7) Share storage space

Using a co-warehousing space is a trend that has become increasingly popular in recent years, especially for small businesses that do not require huge industrial warehouses to store the products they hold and distribute.

While these warehouses are divided into small sections rented to various companies, shared space means cost savings for start-up storage businesses. This means fewer wasted areas gathering cobwebs.

By not having dedicated storage space, costs can be reduced, bills can be shared, and the management of energy efficiency in warehouses can be improved.

Benefits of improving energy efficiency in warehouses:

Cost savings: when you opt for lighting that improves energy efficiency in warehouses and implement systems that help you use your resources better and reduce your waste, you’ll start to see savings on your bills, money you can leverage to grow your business.

Reduce your environmental footprint: today, companies are trying to be more aware of their environmental footprint, that is the impact on the environment of changing raw materials, storing products, and selling them. Thus, when the energy efficiency of warehouses is improved, these companies become more sustainable.

Make your business more competitive: Competitive companies are not only those that offer more and better services but also those that implement simple solutions to more complex processes to improve the energy efficiency in warehouses where they store their goods.

Serviap Logistics helps to improve energy efficiency in warehouses

At Serviap Logistics, we are experts in storage and distribution center businesses in Mexico, Brazil, and the United States, where we care about energy efficiency in warehouses.

Our innovative solutions include signage, floor marking with tape and epoxy paint, racking and collision protection installation, and project management to oversee a warehouse’s setup, remodeling, or relocation from start to finish.

Wherever we offer our logistics services, we do so with quality and attention to detail, making us a leader in the industry. As a result, we are adding more satisfied customers every day from sectors such as automotive, construction, e-commerce, and wholesale, to name a few.

Contact us to learn more about our services and how we can help you improve warehouse energy efficiency.