Table of Contents

In a storage business or distribution center, delimiting transit zones, work areas, and loading and unloading spaces can be optimized with the use of 5S floor marking.

5S floor marking is much more than a system of tape placement; it is a complete methodology that helps optimize productivity through colorful visual marks. These patterns help organize the different zones within the warehouse and have better safety practices.

While there are two types of warehouse floor marking, with strong, durable tape or epoxy paint, perfect for chemical spills and traffic zones, the purpose of 5S floor marking is to achieve organized, tidy, and clean workspaces on an ongoing basis.

This management technique is based on five Japanese principles that began at Toyota in the 1960s and describe each part of the process: seiri (sort), seiton (stabilize), seiso (shine), seiketsu (standardize), and shitsuke (sustain), which we will describe below.

Contact us if you need advice on floor marking in your warehouse. We offer services in Brazil, Mexico, and the United States.

5S floor marking in a warehouse

Seiri (sort)

The first step of the 5S floor marking consists of cleaning the workspace, which means identifying all items not needed in a warehouse, separating, disposing, or storing them for later use. This avoids unnecessary items cluttering essential spaces.

To separate goods or materials, it is necessary to know how often they are used or how essential they are. This hierarchization helps to take advantage of the new cleaner places, delimit them correctly with tape or paint, and make sure they can be used for maximum efficiency.

Seiton (stabilize)

Seiton, the second part of the 5S floor marking process, is related to establishing a method that helps quickly locate materials by color and shape markings. This way, it will be easy to access the goods and use and replace them if necessary.

One of the criteria for ordering materials is the FIFO (first in, first out) concept, which helps to define the first item out of a queue. However, sorting and repetition also make finding a tool or the right objects easier when needed.

Seiso (shine)

The third part of the 5S floor marking method, called seiso, is related to cleaning. After tidying up a work area and ordering its most important elements, it is time to make it shine. The cleaner a workspace is, the less friction there will be for its flow.

SEE ALSO: Warehouse labeling systems: tips to improve efficiency

To keep a warehouse space shining, for example, floor markings can indicate areas for cleaning, storage, transit, loading and unloading, and any other activity within the facility. These markings will remind employees which items should go in these spaces and which should be removed.

Seiketsu (standardize)

The penultimate stage of 5S floor marking is to standardize processes to keep workspaces orderly, clean, and shining. The only way to do this is by detecting irregular or anomalous situations and correcting them on time.

When effective processes are repeated, a routine is consolidated in the workplace, which improves safety and productivity within the warehouse or distribution center. At this point, operators already know, for example, that red tape corresponds to waste, green tape to finished products, yellow tape indicates the flow of goods, and so on.

Shitsuke (sustain)

Finally, shitsuke aims to maintain the benefits of the previous four steps, seiri, seiton, seiso, seiketsu, through the sense of self-discipline of workers and operators within a warehouse or distribution center.

This step seeks to obtain a continuous and reliable verification of the 5S floor marking, which serves as a reminder to keep workspaces with the indispensable elements tidy and clean, as these markings help to give transit indications, indicate hazardous areas, and delimit work zones.

General considerations for 5S floor marking

When implementing 5S floor marking in a warehouse or distribution center, a color code and pattern should be established by following the territory’s safety regulations.

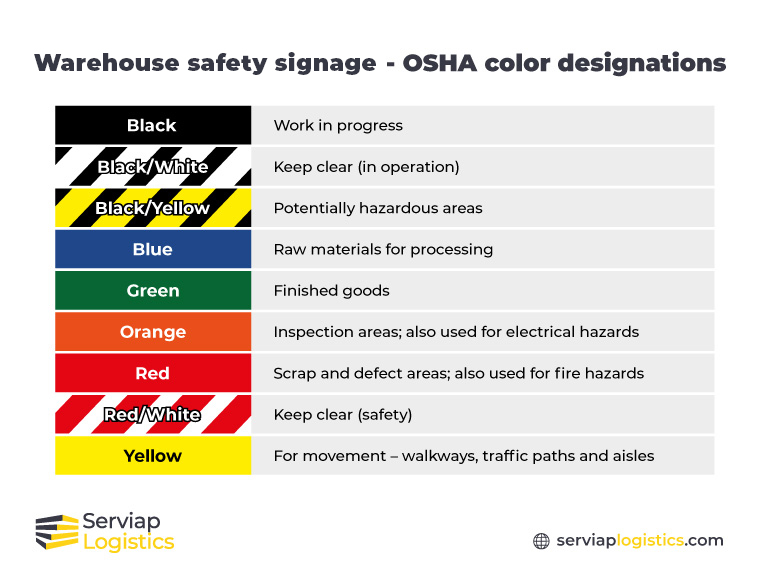

OSHA certification, for example, suggests that black be used for work in progress, black and white for keeping a space clean, and blue for raw materials. Green corresponds to finished products, orange to inspection areas, and red to the retention of defective materials or fire hazards. White indicates where containers or other items are located, while yellow is for the flow of materials, such as aisles, corridors, and traffic areas.

Once the colors for 5S floor marking are established, this information should be shared with all the employees through training and by creating a chart displayed in a central area with each color and its meaning.

Finally, a choice should be made between industrial tapes, usually the most economical and least complicated method, or paint, which requires more planning but is more efficient in high-traffic areas due to its durability.

Whichever method is chosen, 5S floor marking must be done by an expert such as a warehouse setup consultant, and with quality products that guarantee durability, preserve safe spaces, and minimize disruption of processes within warehouses and distribution centers.

Serviap Logistics offers floor marking services

At Serviap Logistics, we handle the installation, remodeling, and relocation of warehouses in Brazil, Mexico, and the United States, territories where we work according to the highest quality standards.

Our services include floor marking, either by taping or with epoxy paint, installation of collision protectors, labeling, signage systems, and shelving supply.

We also offer warehouse project management, which provides companies with a dedicated team to review requirements, define scopes, map deliverables and activities, schedule tasks, submit reports, and more.

Thanks to the quality of our service and personalized attention, we have satisfied partners from some of the world’s largest companies, whose work spans automotive, e-commerce, wholesale, and more.

Contact us to learn how we can help you with your 5S floor marking project and about our other services. And if you liked this article, check out the rest of our coverage.